Laser cutting

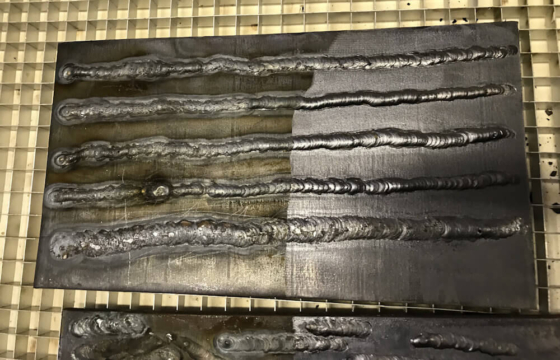

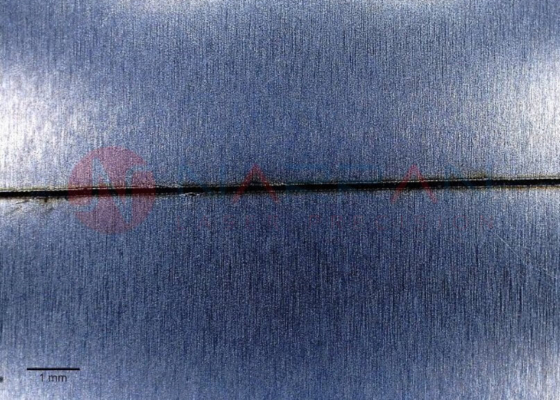

Laser cutting has many advantages over traditional cutting methods (water jet, punches, plasma, ..). It is fast, accurate and the resulting cut is more perfect than other methods used. The installation of a laser cutting machine can significantly reduce the cost of the entire production process. Laser machines can be used for cutting metallic and non-metallic materials.

CO2 laser

It is used in outputs from 100 W for cutting with oxygen (thin materials in range of millimeters), from the order of kW for cutting with nitrogen, argon, air. Compared to other types of lasers, it has low efficiency (10%) and high costs for consumables and service (regular replacement of focusing lenses, mirrors, the laser needs for its operation 4 types of high-purity gases + cutting gas, excitation HF stage is also a consumable , it is necessary to regularly overhaul the resonator and tune the optical path).

Fiber laser

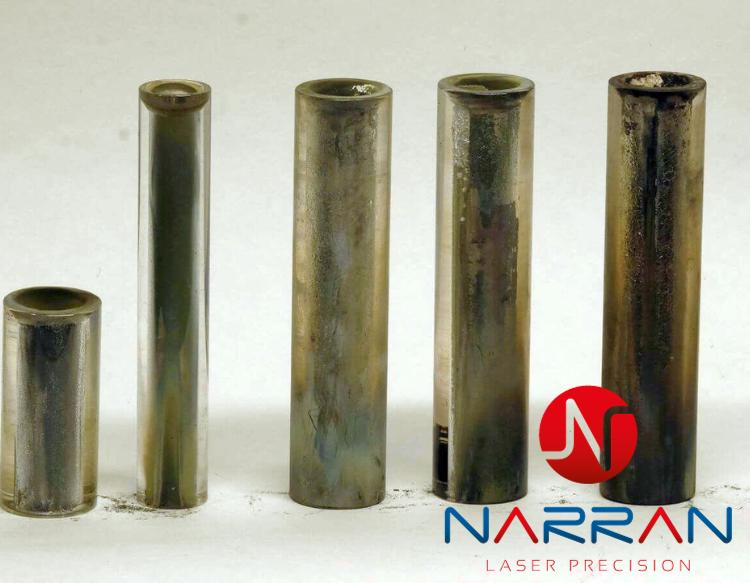

It is used for cutting from 500 W and is profitable up to approx. 3 kW. The laser beam is lead to the machine via an optical fiber. More powerful cutting lasers are usually composed of several modules, and if one module fails, it is possible to continue working with the remaining modules (of course with lower power). The consumables for these cutting lasers are only the cover glass, or the ceramic insulating ring and nozzle. The disadvantage may be a higher purchase price compared to a CO2 laser (it always depends on the application).

Why choose our solution

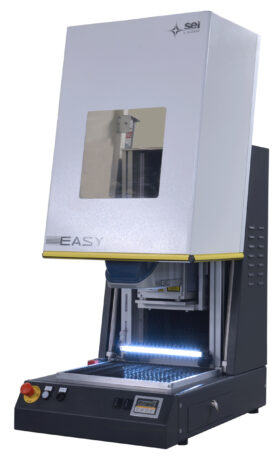

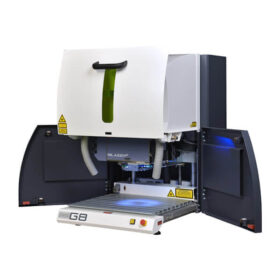

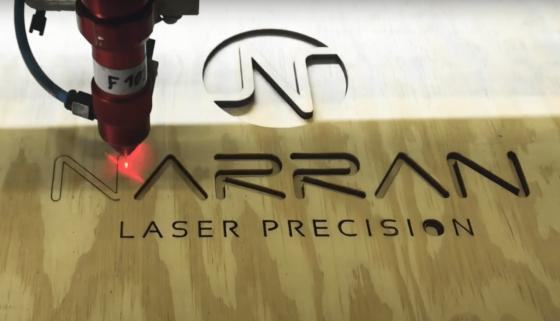

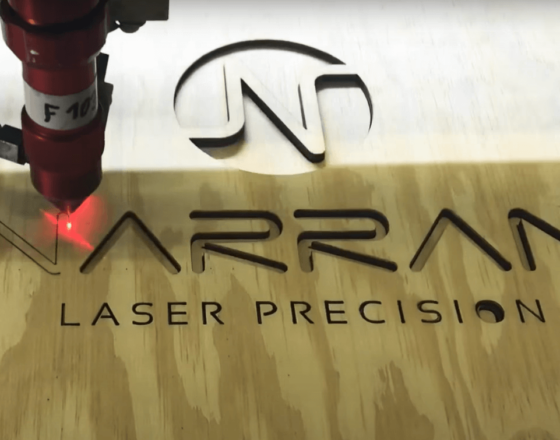

We can advise on the selection of already made solutions (machines), and build a bespoke machine (our own solutions, which we produce under the name of the Narran Veles series. We have many years of experience with cutting various materials and can advise according to customer requirements.

We process the order from the customer's idea, through the selection / production of equipment, to the training and subsequent service of the machine.

We offer testing of your samples on our machines for easier selection of a suitable solution.

We have common spare parts in stock and we solve the service of the machine promptly according to the customer's needs.

Advantages and functions of our lasers

Suitable materials

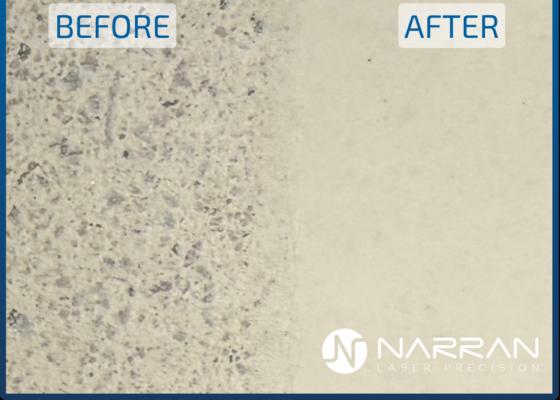

Advantages of laser cutting over conventional methods

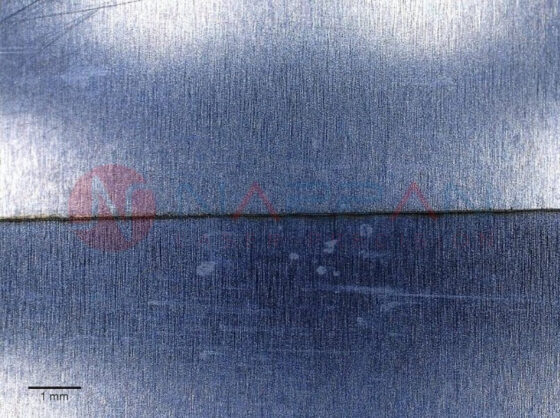

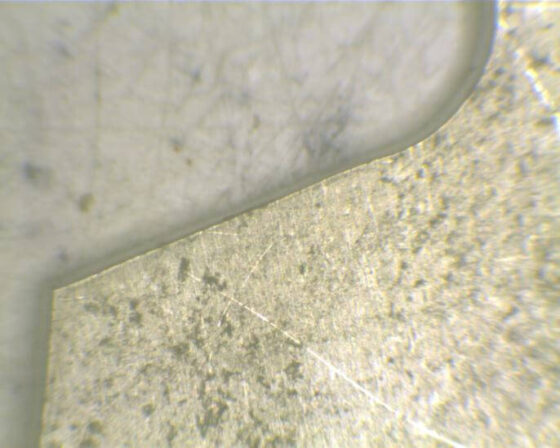

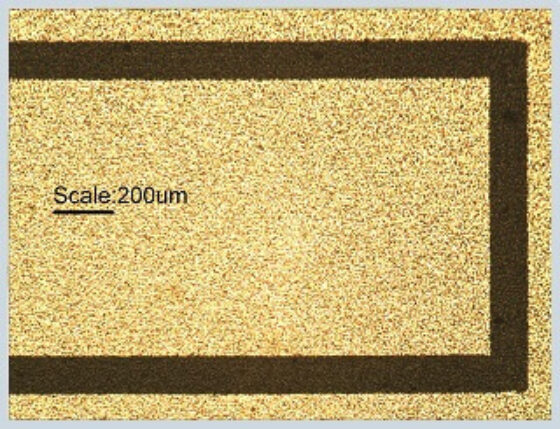

quality, speed and precision of the cut

productivity and work efficiency is high

almost no waste is generated when the material evaporates

the cutting machine can be integrated into an automated workplace

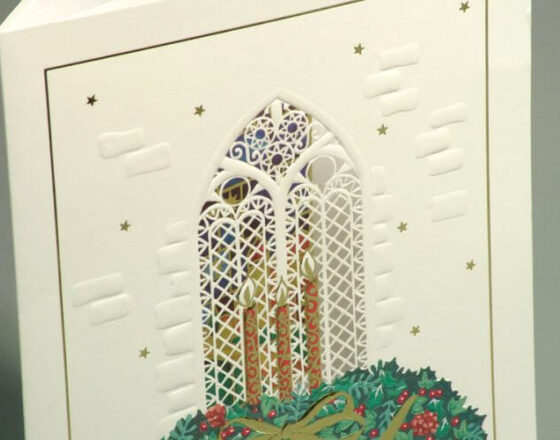

What can a cutting laser be used for?

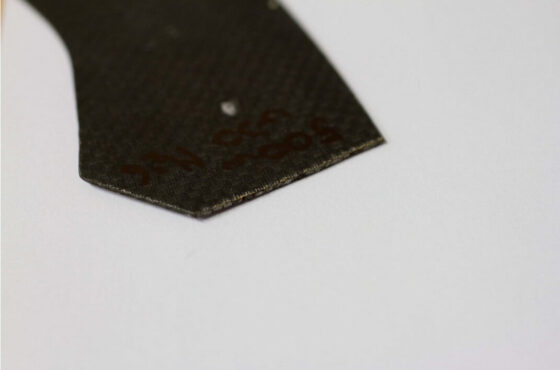

This is how our clients use laser

Our lasers offer

It is suitable as a mobile extraction solution for occasional use, < 1 hour per day.