10 Benefits of Laser Cleaning

Deciding if buying a laser cleaning machine is the right choice for your business? We’ve put together the 10 most important points to answer your most frequently asked questions.

1. Lowest operating costs of all cleaning methods

Our lasers can clean 24/7 with an operating cost of less than €1 per cleaning hour. Unlike sandblasting or pressure cleaning with water, it does not require production to stop.

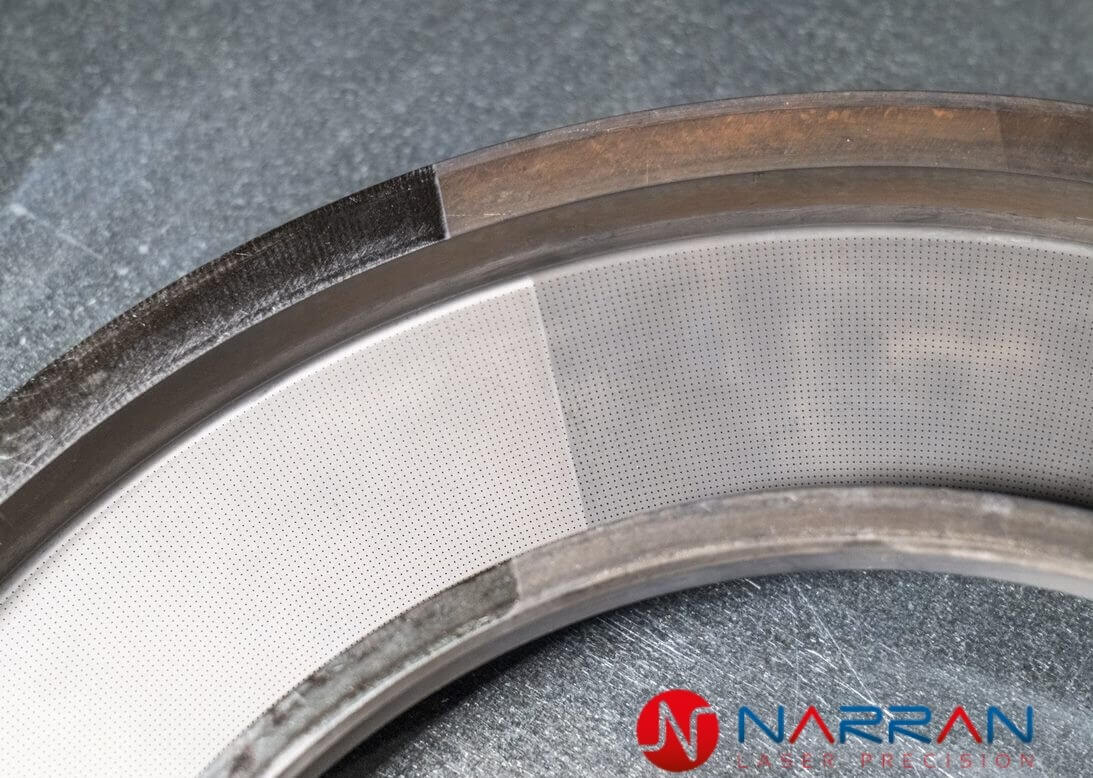

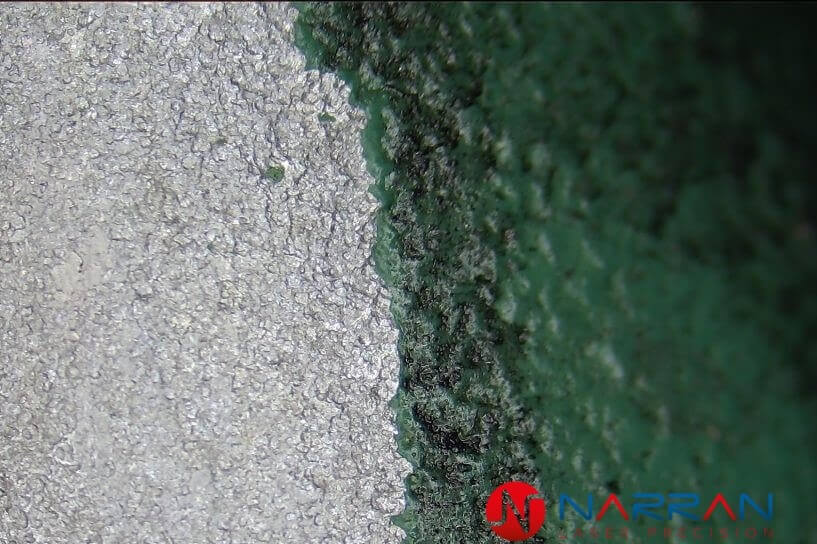

2. The laser will not damage the substrate material

Laser cleaning is a very gentle process that destroys any unwanted surface but leaves the underlying material intact and undamaged.

3. Laser has countless applications

Our laser can be used to clean a large number of unwanted surfaces, most commonly grease, rust and oxidation, paints, inks, oils, PUR foam, varnishes and adhesives, natural and synthetic rubbers, and many more are being added due to the continuous development of materials and industrial advances.

4. Minimum temperature effect on the surface to be cleaned

Laser cleaning is a non-contact, non-abrasive method that is very gentle on the underlying material surface. When properly adjusted, the laser beam will hardly heat the surface, even after deeper cleaning you can keep your hand on the surface of the material. We can clean hot surfaces (inside injection molds, baking sheets), cold or wet surfaces in the same way.

5. All our lasers are mobile

The entire process of loading and unloading the laser into the car and preparing it for cleaning takes approximately 10-15 minutes. Our lasers are able to respond immediately.

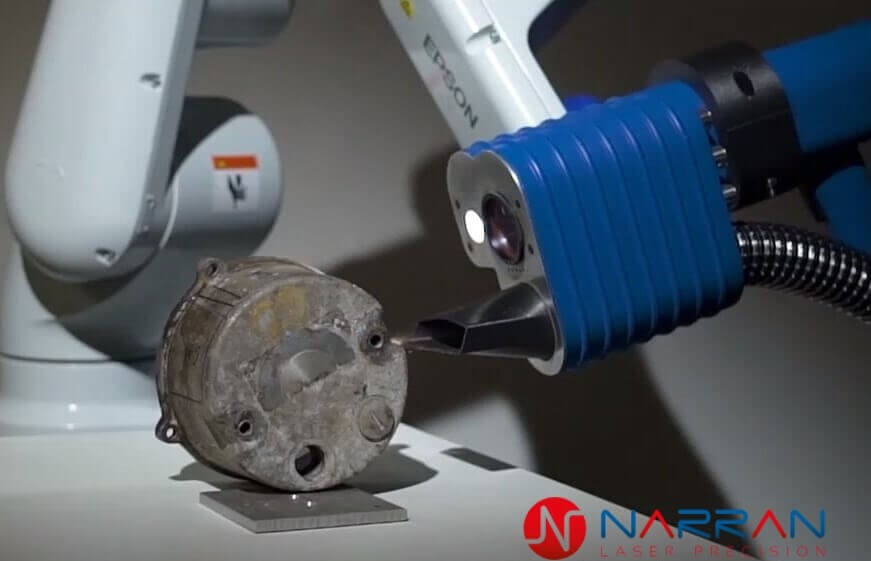

6. Manual, robotic or integrated into the production line

Our aim is to perfectly meet the needs of your business, our ROD lasers can be handheld, equipped with a robotic arm or integrated directly into the production line without having to stop the operation. They can also be integrated backwards after delivery of the handheld form, communicating with a robotic manipulator or with external equipment via industrial communication protocols.

7. Easy laser maintenance

Modern fibre lasers have a very long lifetime of up to 200,000 operating hours and require almost no maintenance. Normally no adjustment, calibration or replacement of spare parts is required. All these benefits allow us to describe these lasers as virtually maintenance-free.

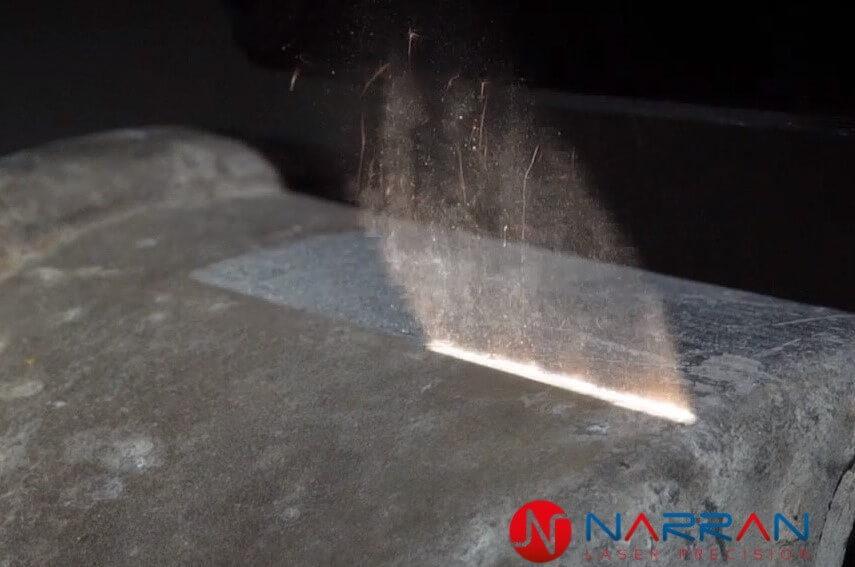

8. Laser cleaning is green

Compared to conventional cleaning methods, almost no waste is generated during laser cleaning because most of the contaminants are evaporated. Another benefit that makes this method green is the minimal energy consumption. Up to the ROD 500, the connection is 230V (16) or 115V (60hz).

9. Easy setup for countless applications

Thanks to the possibility of adjusting the laser resonator properties, from 10-100% power, frequency, pulse length, as well as the optical properties of the laser beam, you can use one laser to clean, for example, historical objects, polished surfaces at very low power, as well as deep rust or epoxy paints at very high power

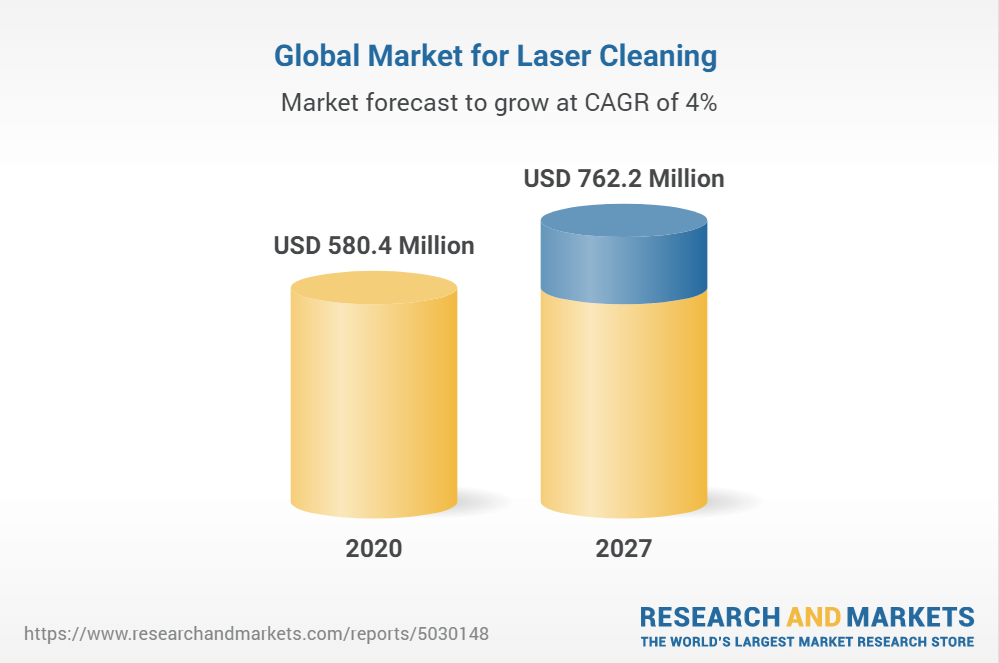

10. Laser cleaning technology is a rapidly growing industry

According to researchandmarkets.com, the laser cleaning market was valued at USD 580.4 million in 2020 and is expected to reach USD 762.2 million by 2027, at a CAGR of 4%