Next generation laser process head

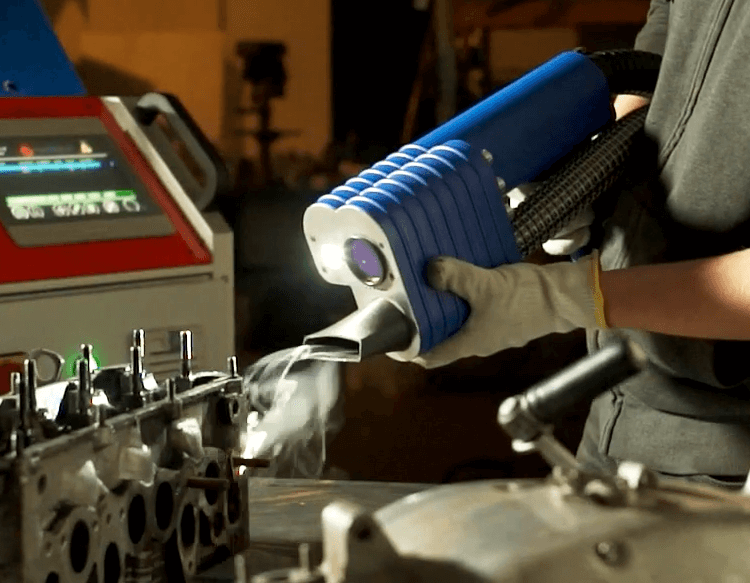

Undoubtedly, the biggest advantage of ROD laser systems against other cleaning laser devices is the perfectly thought out process head, because you, as a user, will hold this very important part of the laser cleaning machine in your hand every day.

The 3rd generation of the process head of the cleaning laser is the result of 7 years of development and improvement under the strict supervision of our engineers in the field of optics and mechanics.

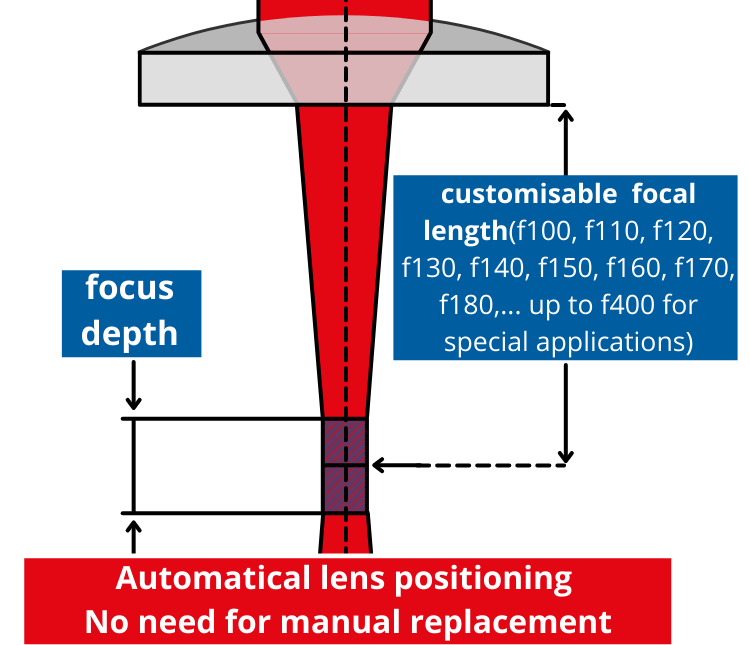

1. Focus setting

The focusing distance affects the areal density as well as the distance of the process head from the area to be cleaned. Compared to other conventional cleaning systems, we offer automatic change without physical intervention and thus manual lens replacement. The focusing distance can be adjusted in the range of millimeters, so you can achieve results that were previously unthinkable.

To be able to reproduce the functioning of our optics on other systems, you would need to have dozens of focusing lenses worth tens of thousands of euros. At the same time, the laser optics are very sensitive to dirt, and any opening of the laser head when replacing the lenses can lead to serious damage to the internal optics, mirrors and process fiber, which can lead to unnecessary damage.

2. Ergonomic cleaning head grip

Although laser cleaning is a non-contact method, it is still a relatively demanding physical work. The laser process heads of ROD machines are light, have an ergonomic grip and, above all, it is possible to put an optical cable over the shoulder or manipulate it in various ways if necessary for easier work.

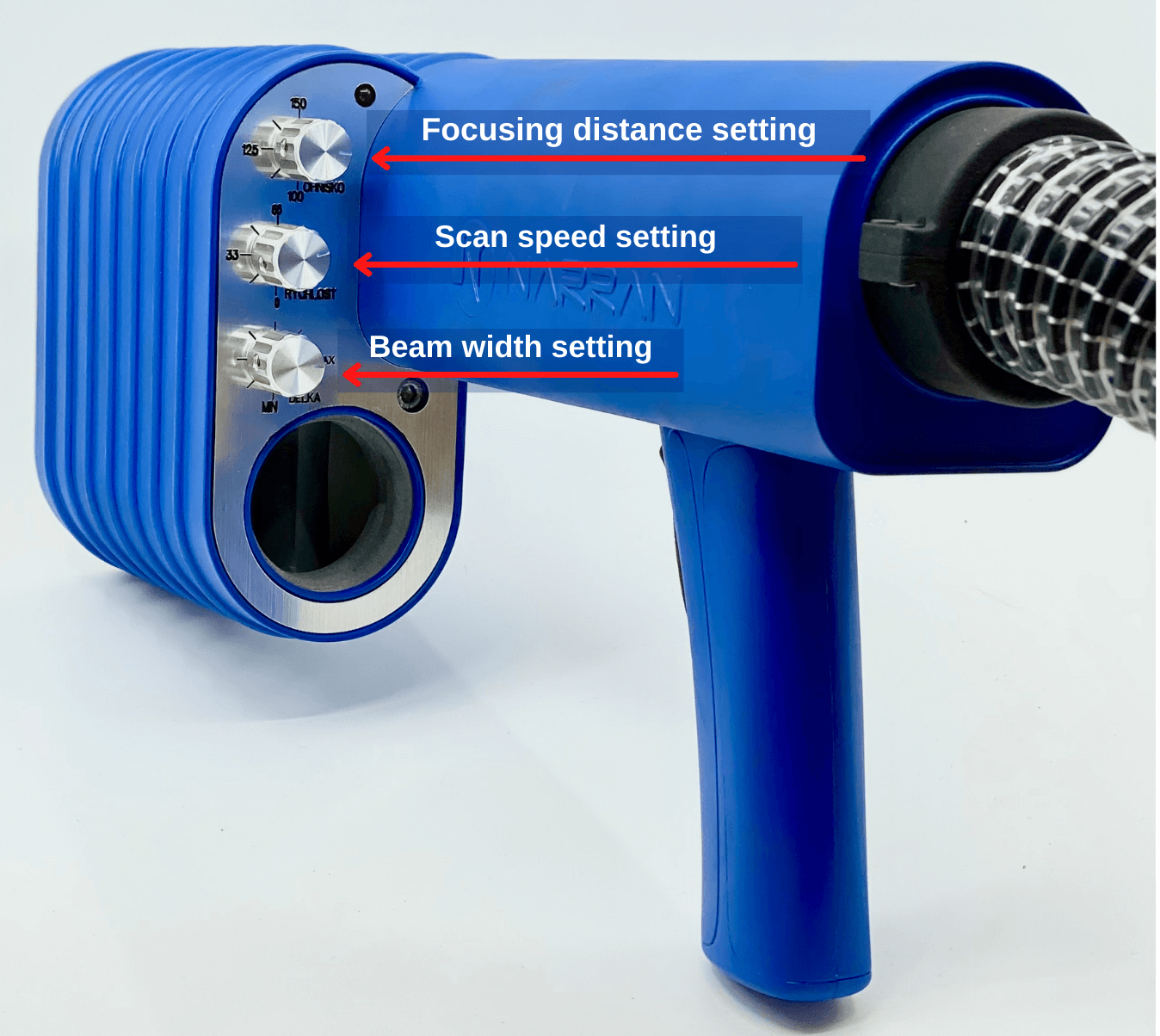

3. Setting parameters directly on the process head

Thanks to the conveniently designed controls located directly on the back of the head, you do not have to stop cleaning and set the most important cleaning parameters on the machine display during work.

4. Active cooling to prevent overheating

ROD 200,300,500 and 1000 models all have actively water-cooled process heads. This can guarantee its smooth operation even in demanding climatic conditions (cleaning outdoors in winter and summer, inside industrial molds, directly on production lines), even in continuous three-shift operation. Our machines work all around the world from Australia to Russia, so we know how to properly design and control important parameters for our systems.

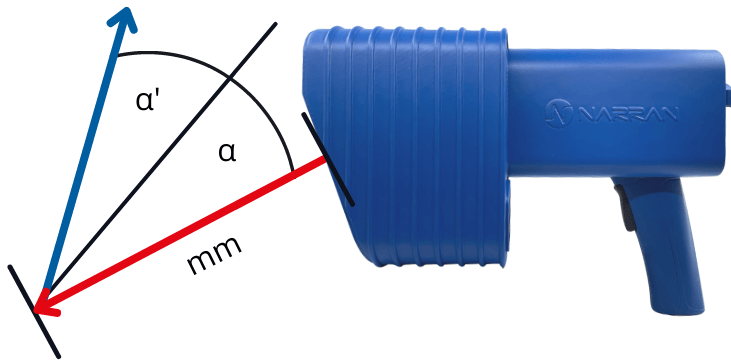

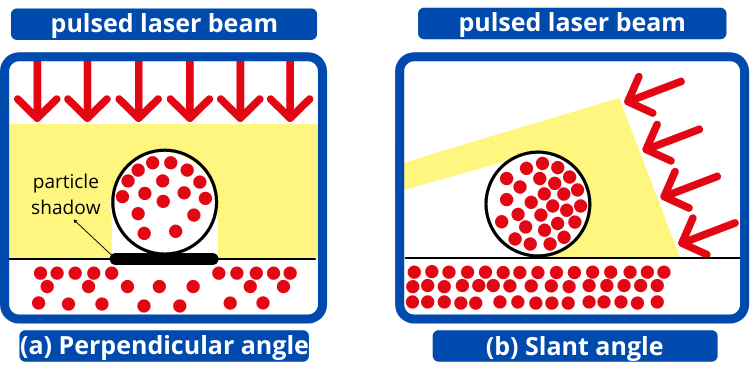

5. Cleaning at an angle

Angle cleaning combines two main advantages of vertical and horizontal cleaning.

Angle cleaning is used to increase the efficiency of laser cleaning. The laser beam does not fall perpendicular to the sample, but is guided at a certain angle. ROD laser heads clean at an angle without the need for impractical tilting and twisting.

Thanks to this, the laser radiation in the dust or plasma cloud, which is caused by the explosion or ionization of the irradiated part of the material or the air, is not absorbed to such a large extent. This occurs especially during ablation with high intensity and repetition frequency. Another advantage is the several times larger effective cleaning area of the beam.

6. Suction with extended extraction nose

Our ergonomic process heads from the 2020 model series for ROD 200,300,500 and 1000 have the option of attaching the suction hose directly to the head for maximum prevention against the possible danger of inhalation of vapors.

Dangerous fumes and particles can be generated during laser cleaning and therefore we consider efficient extraction and filtration of fumes from the zone where the cleaning takes place as a necessary part of laser cleaning, even though it is often ignored by low-quality manufacturers.

Extended extraction nose

Extraction is most efficient as close as possible to the laser process itself for eliminating the possibility of releasing particles and gases into the air, thus increasing work safety. It also prolongs the service life of the protective optics.

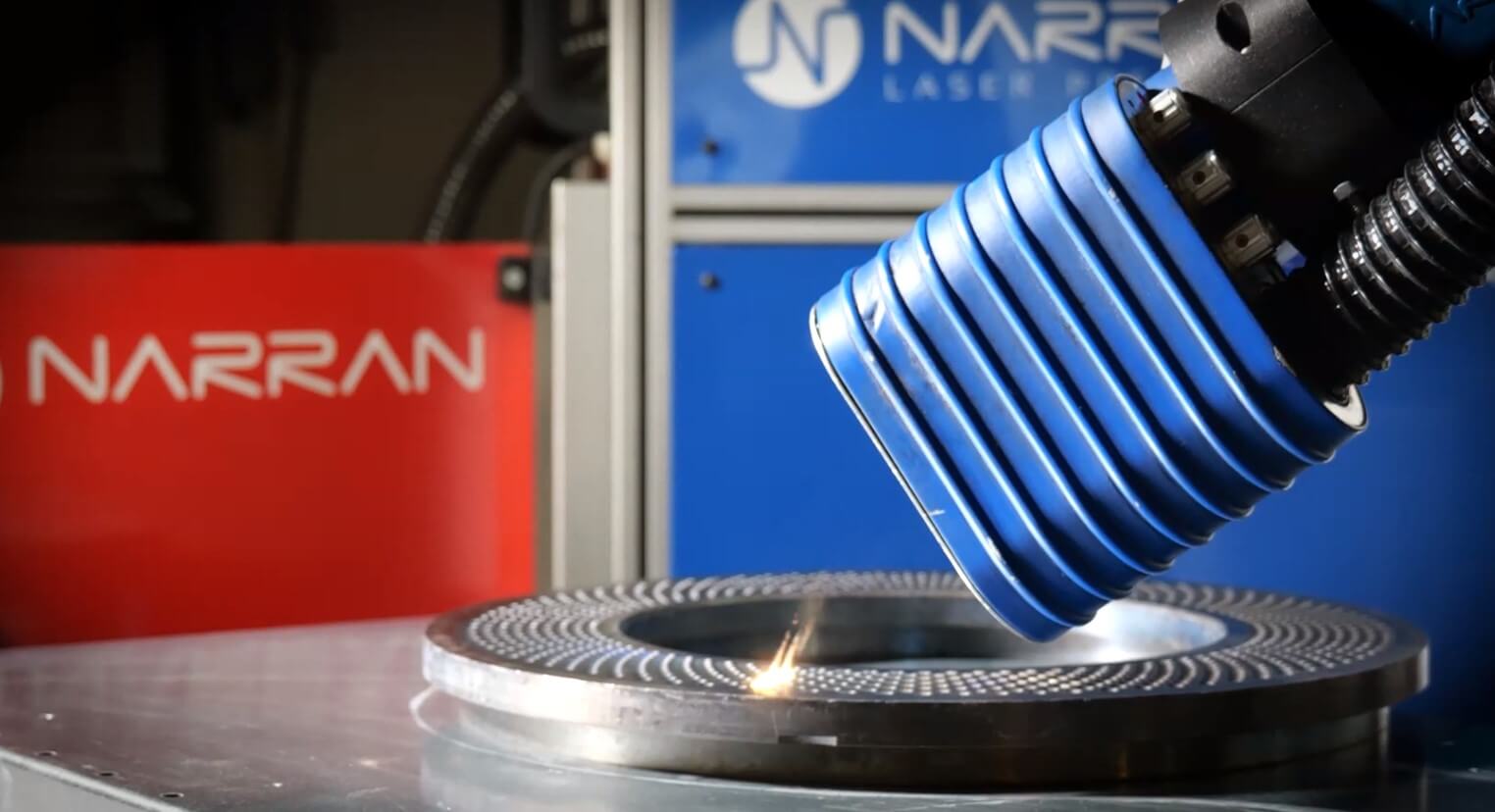

7. Possibility of mounting on a robotic arm

All models of our cleaning lasers can be attached to a manipulator, rails or a robotic arm, even long time after purchasing the laser. The industrial PLC is ready for communication with superior systems or external laser beam triggering,

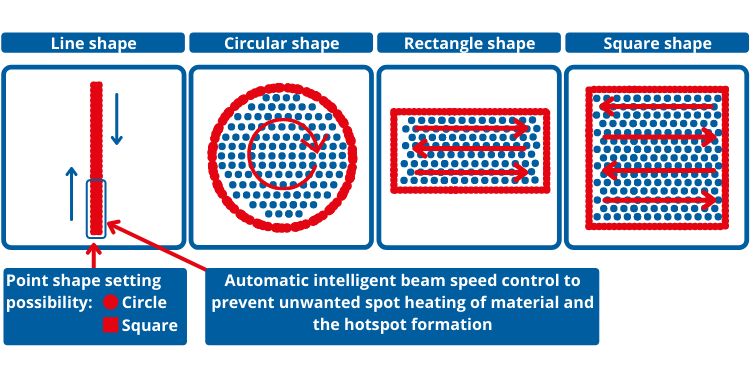

8. Adjustable beam shape

Our cleaning lasers use a scanning system that is made specially for smooth and even laser cleaning in several beam shapes. Thanks to the adjustable beam shape, our lasers not only increase efficiency and accuracy in cleaning, but can also get into textured and grooved surfaces that basic laser cleaning cannot handle.

9. Optics protection

All ROD laser heads have double protection against unintentional penetration of dirt into the interior of the process head and automatic blowing of the optics. The blower ensures a longer service life of a single consumable part of the laser – a cover glass that protects the lens from contamination. The cover glass is also easily replaceable (replacement takes less than a minute).

10. Slant beam output

Thanks to the slant output of the laser beam, the head eliminates back reflections of both laser radiation and released dirt and fumes. The head is therefore less stressed by impurities and heat, so it has lower maintenance requirements, which has a positive effect on its overall service life.