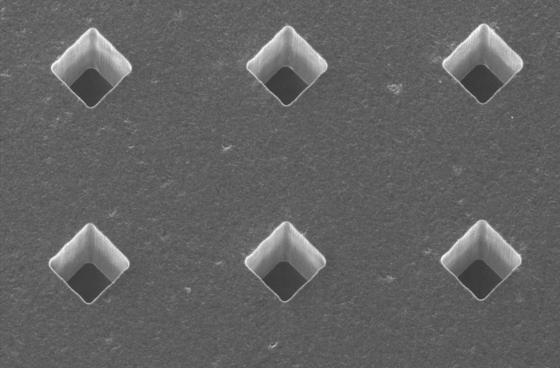

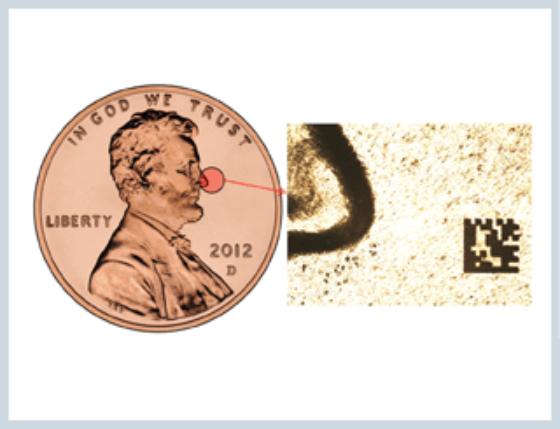

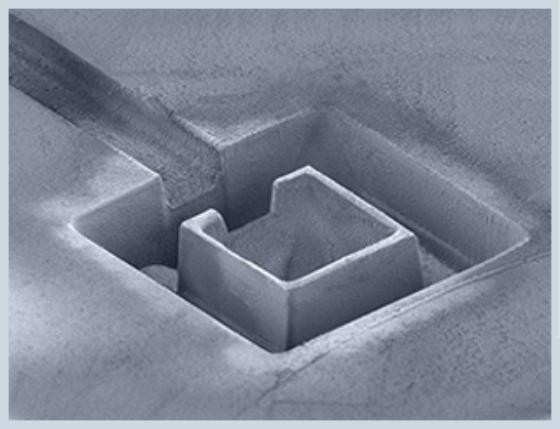

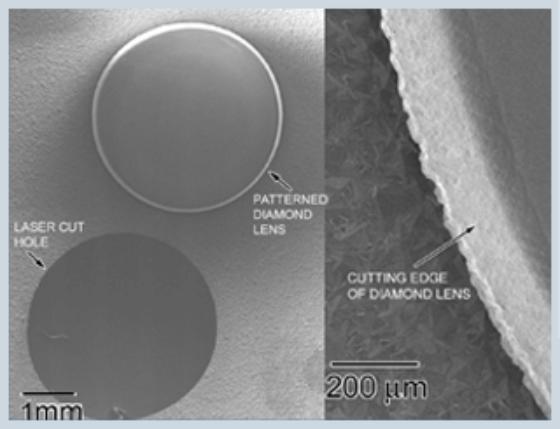

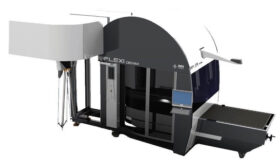

Laser micromachining

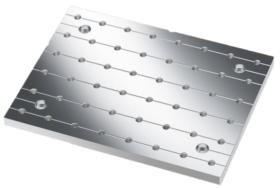

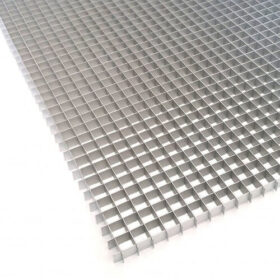

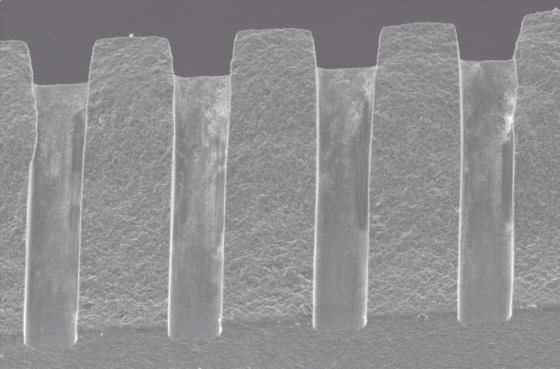

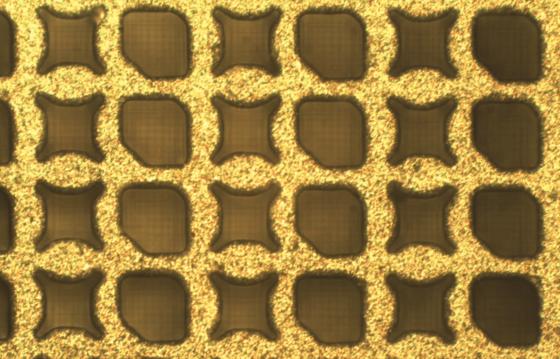

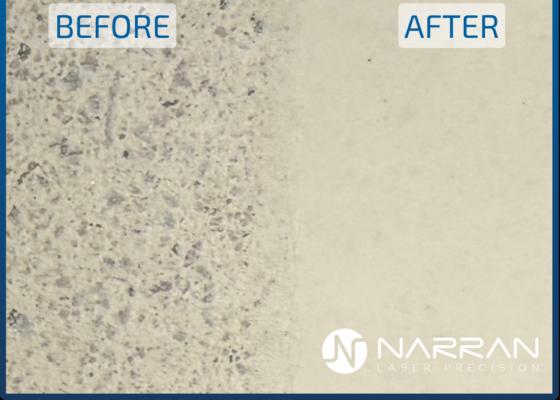

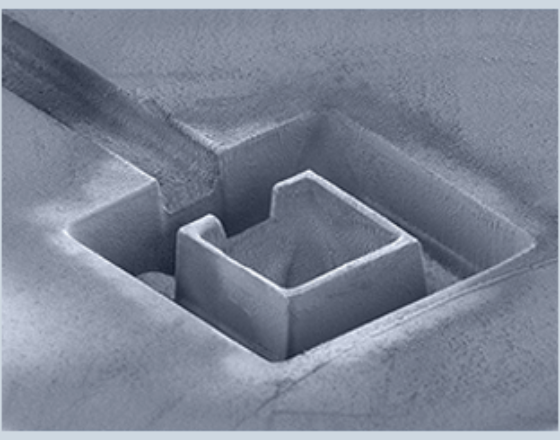

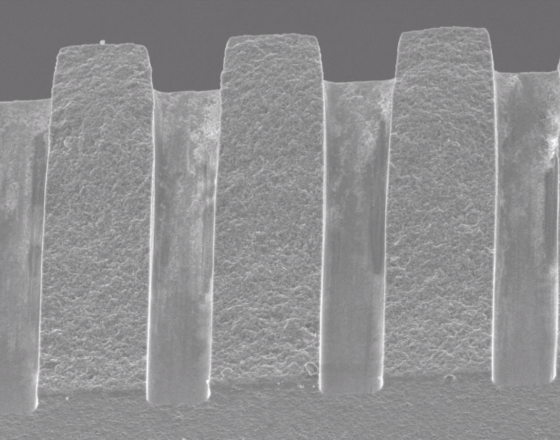

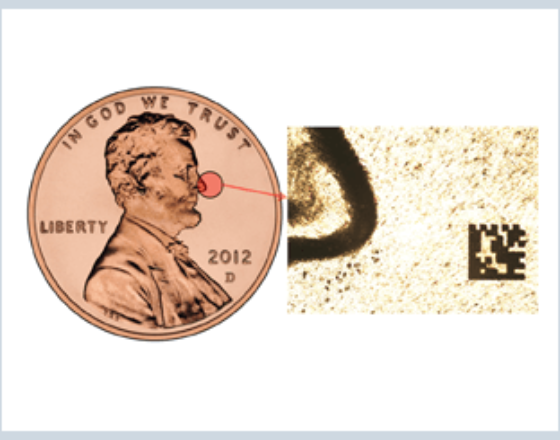

The trend of today is speed, miniaturization and accuracy. For this reason, new technologies are constantly being sought that could process a wide range of materials in very small dimensions. Of course, there is a huge precision with which the object must be machined. Thanks to the focusing of the beam into micron dimensions, the use of lasers is very convenient.

Why choose our solution

We offer the possibility of testing samples or a feasibility study

We can individualize our machines according to your needs

We will arrange the turnkey contract, including installation and training

We will quickly supply spare parts and provide a complete service

Advantages and functions of our lasers

Suitable materials

Advantages of laser micromachining over conventional methods

Laser is a non-abrasive method

Fully adjustable machining speed

Possibility to set machining details

Repeatable accuracy and possible process control

What can a machining laser be used for?

This is how our clients use laser

Our lasers offer

It is suitable as a mobile extraction solution for occasional use, < 1 hour per day.