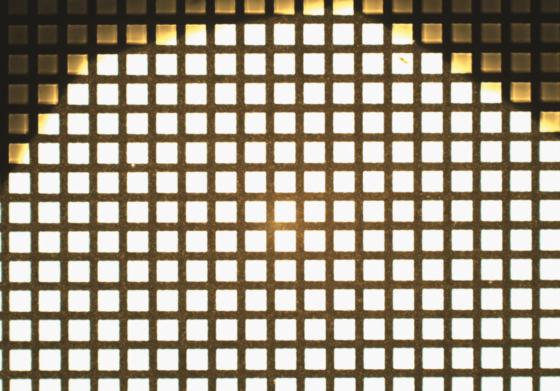

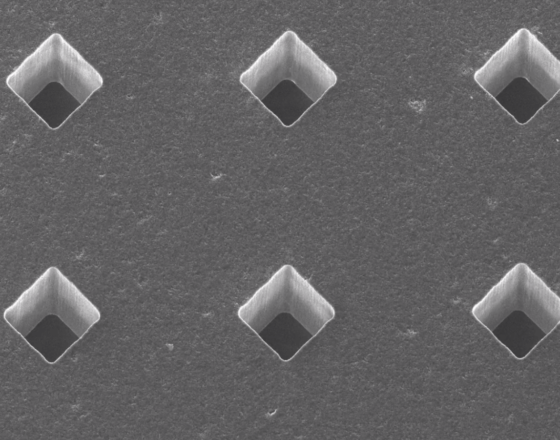

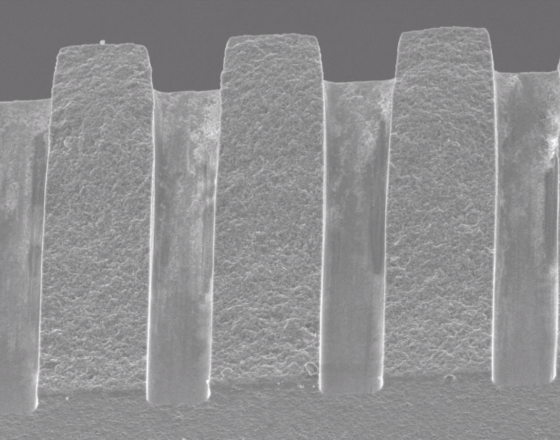

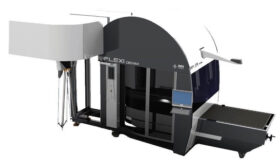

Laser drilling

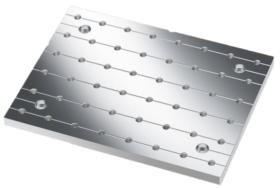

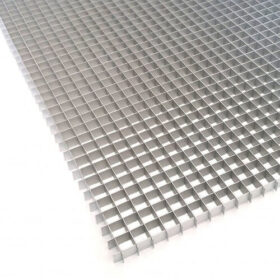

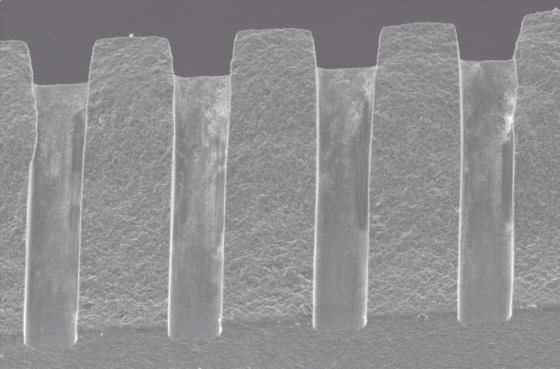

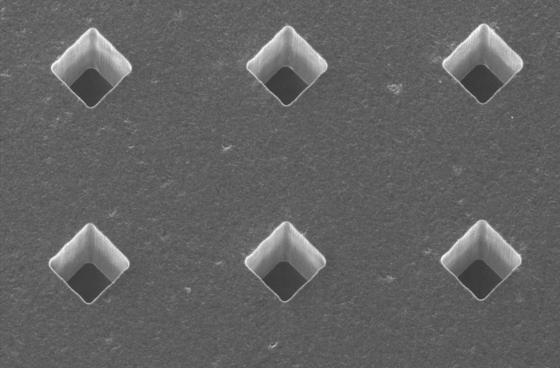

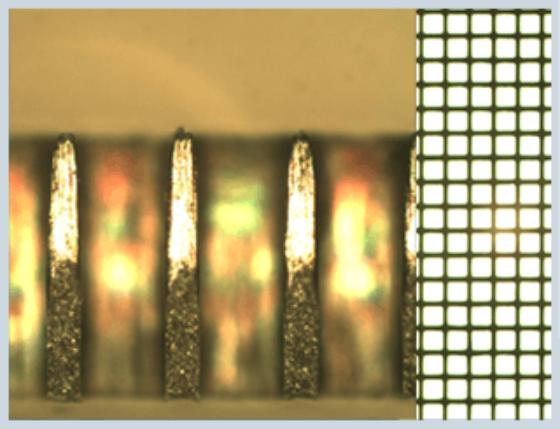

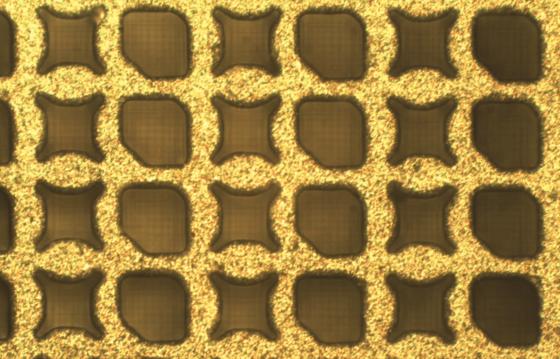

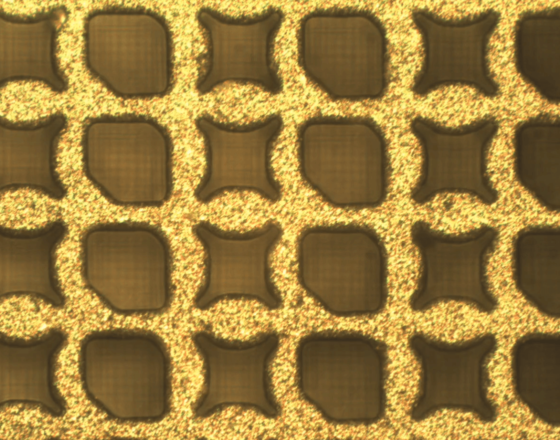

Laser drilling, like marking or microperforation, is based on the evaporation of material at the place of drilling. As a rule, high-power pulsed lasers with high energy density and special drilling methodology are used – single pulses, repeated shock pulses, hole cutting, spiral drilling, etc.…

Why choose our solution

We offer the possibility of testing samples or a feasibility study

We can individualize our machines according to your needs

We will arrange the turnkey contract, including installation and training

We will quickly supply spare parts and provide a complete service

Advantages and functions of our lasers

Suitable materials

Advantages of laser drilling over conventional methods

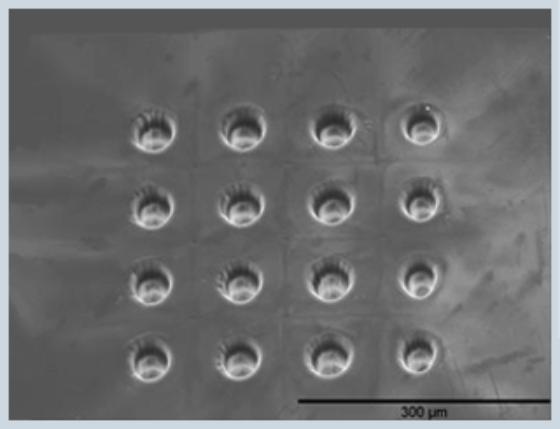

Drilling of hard and brittle materials, eg carbides, ceramics, glass

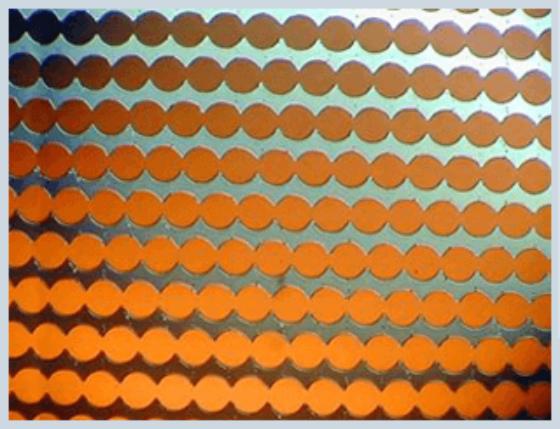

Up to several thousand holes per second

Possibility to change the size, shape and angle of drilling during the process

Repeatable accuracy and possible process control

What can a drilling laser be used for?

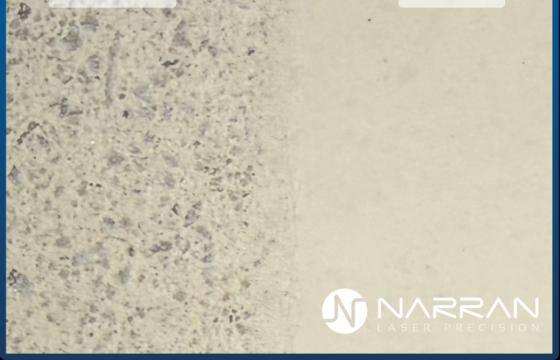

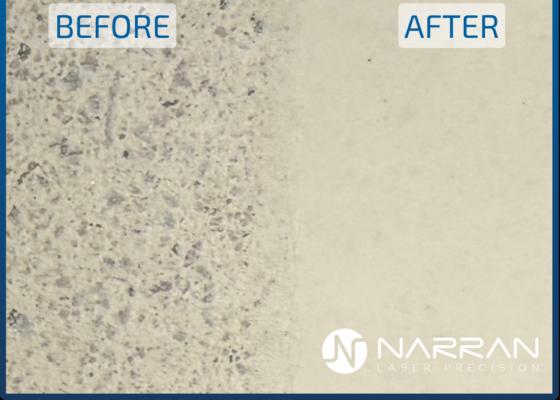

This is how our clients use laser

Our lasers offer

It is suitable as a mobile extraction solution for occasional use, < 1 hour per day.