Laser cleaning

Laser cleaning is becoming more and more popular for its speed and simplicity. Do you need to clean something, see how laser cleaning works, or directly recommend and install a cleaning laser? Contact our company.

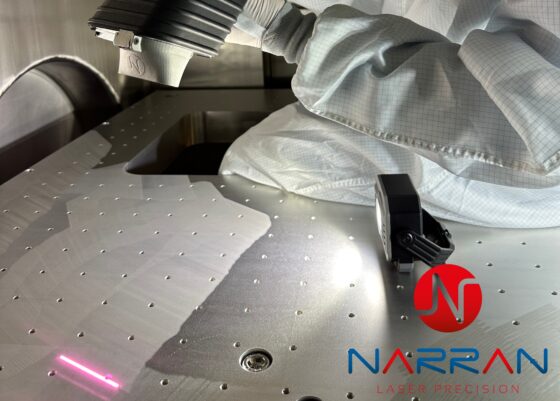

Narran is a direct Czech manufacturer of laser cleaning systems. Depending on the needs of the application, we can design and integrate the laser into production lines, build a robotic workplace or supply a portable mobile laser for a wide range of applications.

Why choose solution from Narran

We know the machine from the very beginning, we were the first to start producing cleaning lasers in the Czech Republic and now we export them all over the world.

We manufacture fully industrial machines from the world's best components with the addition of our unique know-how

Upon agreement, our machines can be tried and tested both with us and at your place

Testing, selection of a suitable laser, installation and training, service support

Advantages and functions of our lasers

Suitable materials

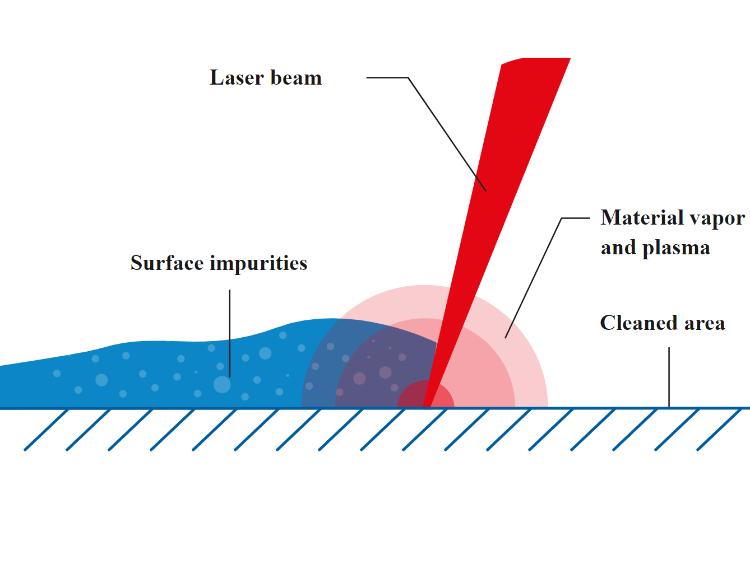

Advantages of laser cleaning over conventional methods

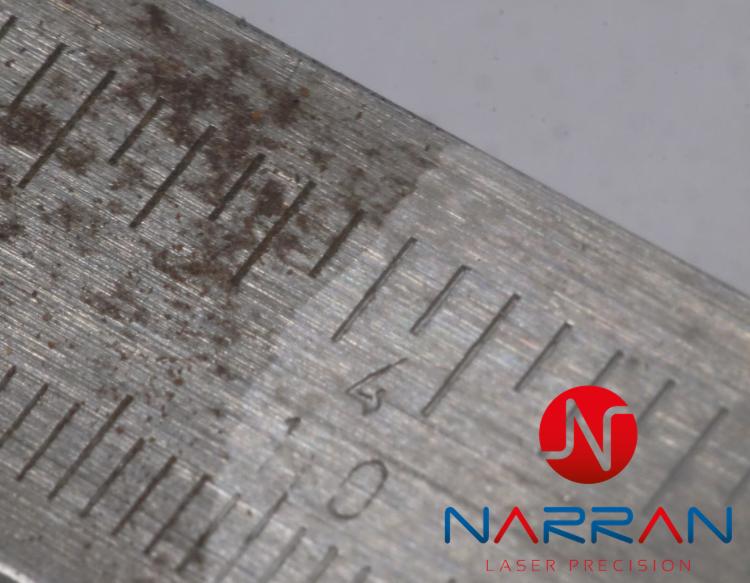

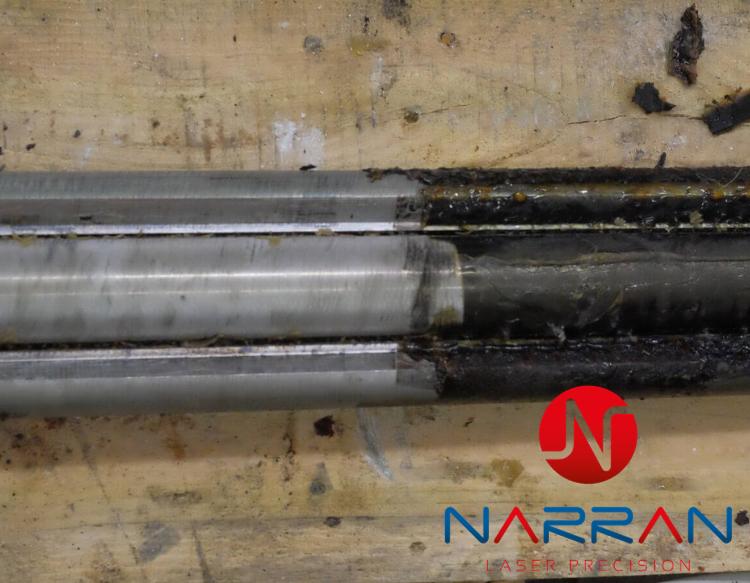

Without damaging the substrate. During sandblasting and blasting, the surface can often be damaged

You will always achieve the same result

Very fast compared to conventional methods

Low operating costs, maximally 1 EUR / hour.

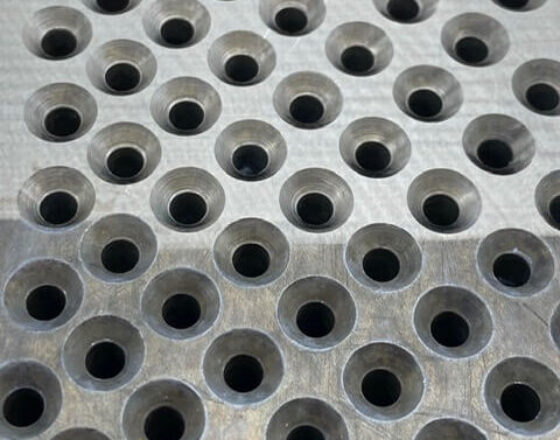

What can the cleaning laser be used for?

This is how our clients use laser

Our lasers