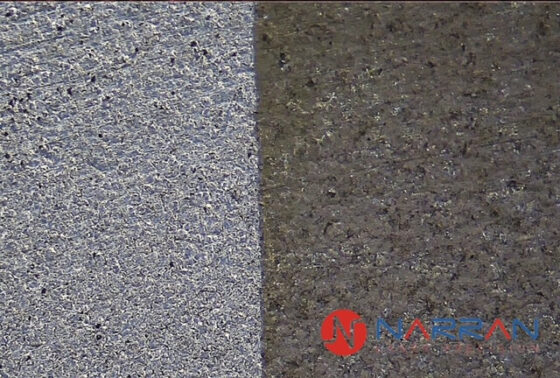

Surface preparation

The ROD cleaning machine excels in preparing various surfaces for painting, welding and soldering. Thanks to this technology, the surface has increased adhesion and the paint/varnish adheres better. Likewise, the weld is stronger due to the absence of contaminants that could otherwise compromise its integrity.

- Fast weld preparation (up to 5m/min)

- The entire process can be monitored to ensure consistent quality

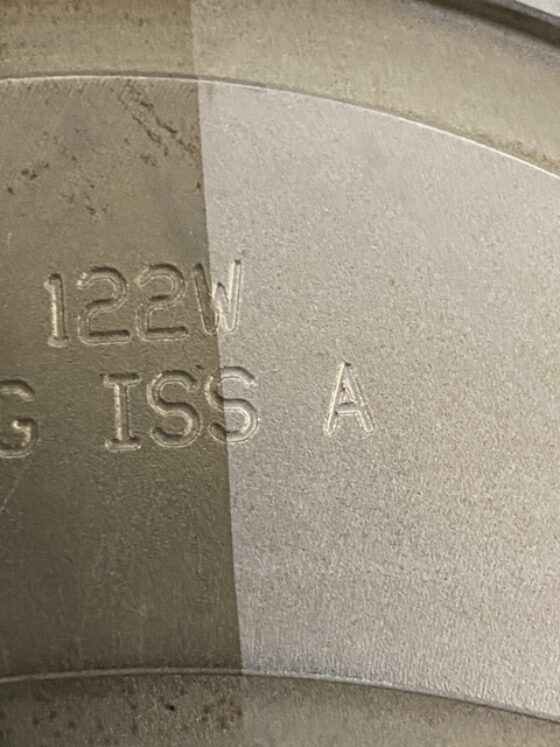

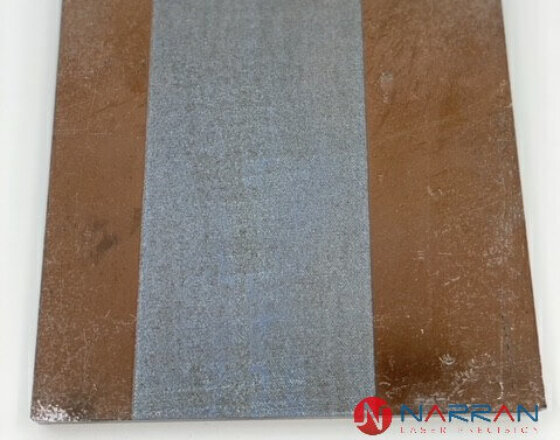

Removal of rust

Fiber laser cleaning quickly and accurately removes rust without damaging the underlying metal. It is most commonly used for surface preparation for welding to increase the strength and quality of the weld, or painting or staining to increase the adhesion of the paint to the metal.

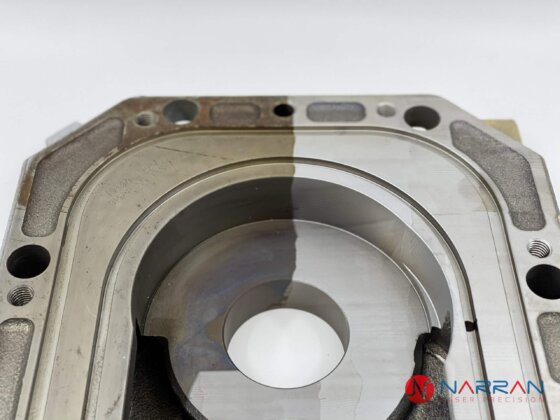

Removing oxidation

Laser oxidation removal is a suitable method of preparing metal for any surface treatment, but is most useful as a preparation for welding aluminium. It is also used after welding to remove oxides from stainless steel.

Surface preparation of metals for bonding

The laser finds another use in the preparation of metals for bonding, as it is able to create a perfect surface free of impurities and thus ensure perfect adhesion and strength of adhesives.