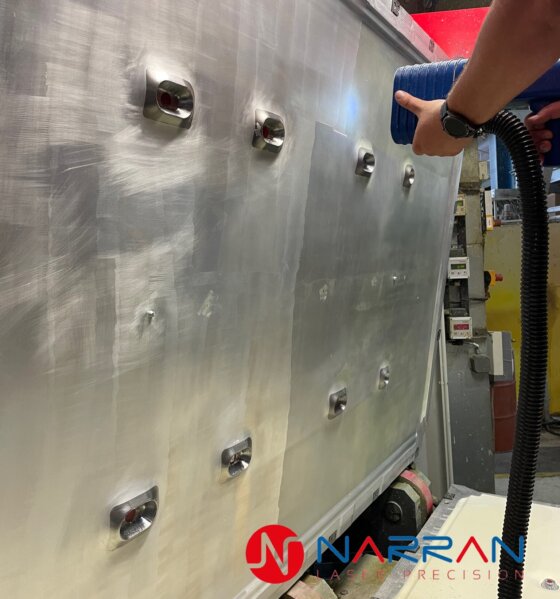

Cleaning plastic moulds

Cleaning speed is also crucial for cleaning plastic moulds, and here too the laser is an ideal solution not only because of its speed but also because it is gentle on the substrate material (mould), which is susceptible to damage (especially by sandblasting).

Another reason is the often high gloss of mould surfaces (and the resulting products). The laser is able to guarantee that the high gloss will not be compromised.

Cleaning of glass moulds

Glass moulds are extremely difficult to clean. In the case of glass products (e.g. bottles), the volume of the product must not be increased, so it is important to perfectly preserve the base material by cleaning. At the same time, these moulds contain countless small openings to ensure air leakage.

The laser is able to thoroughly clean both the air leakage holes and the mould itself without any damage.

Cleaning of food moulds

Hygiene is a key aspect for cleaning in the food industry. Food processing conditions are very strictly controlled in terms of cleanliness and must therefore be cleaned with an emphasis on ecology.

Laser is the ideal solution in this case, as it is a very thorough cleaning process and it is also easy to integrate into the production line.

Cleaning rubber moulds

The decisive element for cleaning rubber moulds is speed. In this case, the laser has a noticeable advantage over conventional cleaning methods (sandblasting, high-pressure cleaning, chemical cleaning), as it can do the same job in a fraction of the time (especially for the widely used aluminium moulds).

The laser is also suitable for cleaning very heavy contamination, which can otherwise be a problem for conventional methods.

Removal of PUR foams, adhesives, separators, sealants, waxes

Mainly from production moulds, tools, presses or rolling moulds.