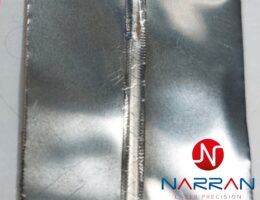

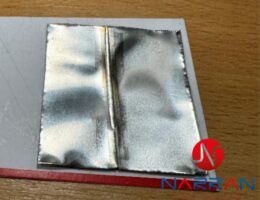

Welding of thin stainless steel sheets

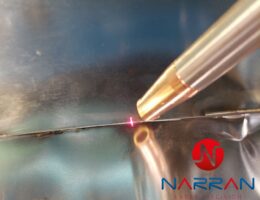

We have achieved exceptional accuracy and minimized deformation in testing welding 0.2 mm thick sheet metal.

Project description

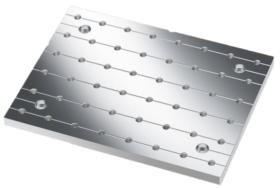

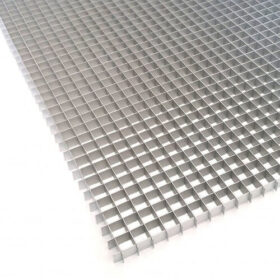

Recently, we have implemented a unique project of welding thin stainless steel sheets with a thickness of only 0.2 mm. This project focused on proving the accuracy and efficiency of modern laser welding technology, using a Theo MA35 handheld laser welder.

Used technologies and materials

- Technology used: Theo MA35

- Material thickness: 0.2 mm (stainless steel sheet)

- Welding speed: 10 mm/s

- Power: 20% (160 W)

- Mode: Pulse

Progress and results

During the process, a high precision joint was achieved that met the demands for quality and aesthetics. Pulsed laser welding ensured that thermal deformation of the material was minimised, which is a key factor when working with thin sheet metal.

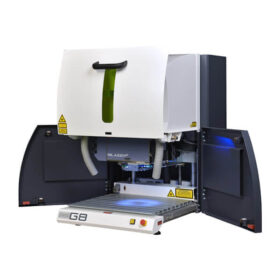

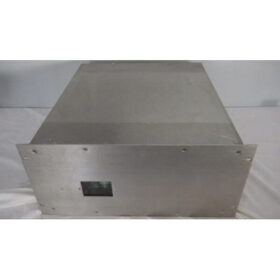

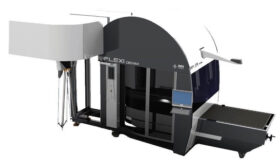

Theo MA35

Theo MA35 is an advanced laser welder designed for precise and efficient welding of thin materials. This system features superior workmanship and flexibility that makes it easy to work even in challenging conditions. Key features include:

- Precise parameter settings: fine tuning of power, pulse length and frequency ensures perfect results even when working with thin sheets.

- Compact design: the ergonomic design facilitates handling while minimizing space requirements.

- Process stability: high quality optical components and precise control ensure stable and reliable welding.

- Flexible applications: suitable for manual work and automated processes, including integration with robotic systems.

- Material protection: integrated shielding gas system minimizes oxidation and ensures aesthetic appearance of the weld.

Progress and results

During the process, a high precision joint was achieved that met the demands for quality and aesthetics. Pulsed laser welding ensured that thermal deformation of the material was minimised, which is a key factor when working with thin sheet metal.

Automation of the process

We are able to automate the process on an XY plotter or a six-axis robot. This process is up to 10 times faster than conventional methods and the resulting weld is beautifully smooth and clean without the need for further adjustments.

Conclusion

This project proves that modern laser welding technology offers significant advantages in the processing of stainless steel sheets, even in the thinnest designs. If you have any questions or need a similar solution, please do not hesitate to contact us.

Related machines

It is suitable as a mobile extraction solution for occasional use, < 1 hour per day.