SEI Laser

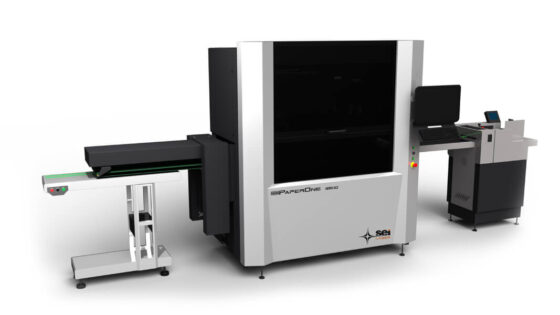

Narran is the exclusive distributor of SEI Laser lasers in the Czech Republic

Why choose SEI laser solutions?

All SEI laser systems are manufactured in the Curno and Buja plants, where quality and attention to detail come first.

SEI laser systems offer benefits in terms of environmental sustainability, which in the long run will bring benefits in terms of reduced costs.

SEI has been on the market for almost 40 years and maintains its uniquely high standard of quality and pro-customer approach.

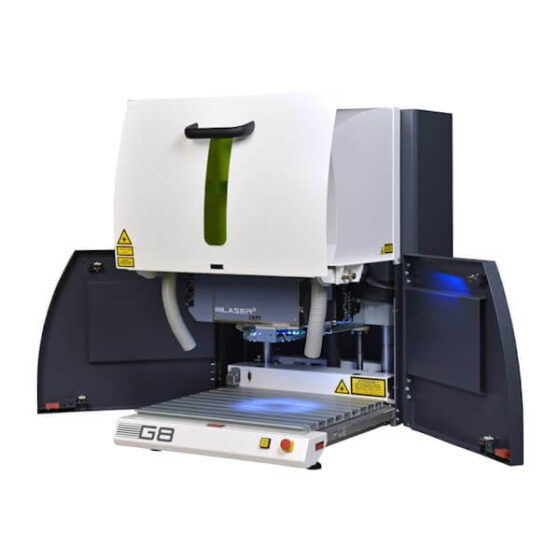

All SEI laser systems use the patented ICARO software, which works on the Windows platform™, making it easier to connect to the latest versions of CAD-CAM on the market.

What makes SEI lasers stand out

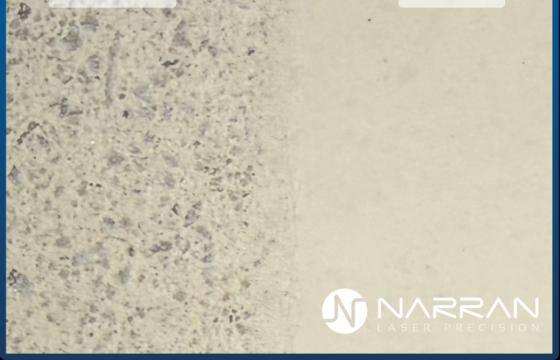

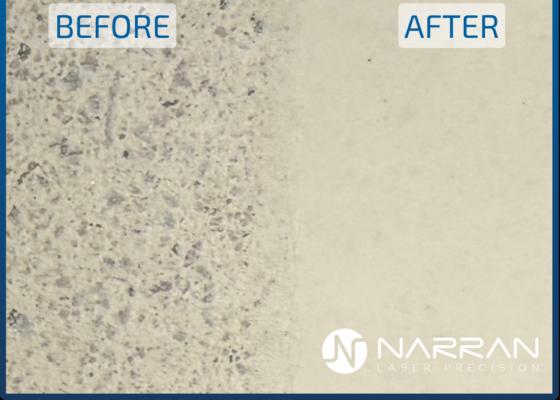

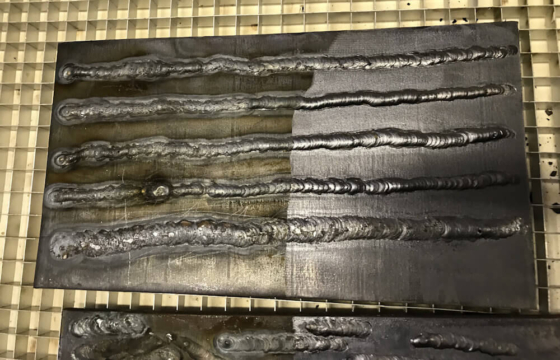

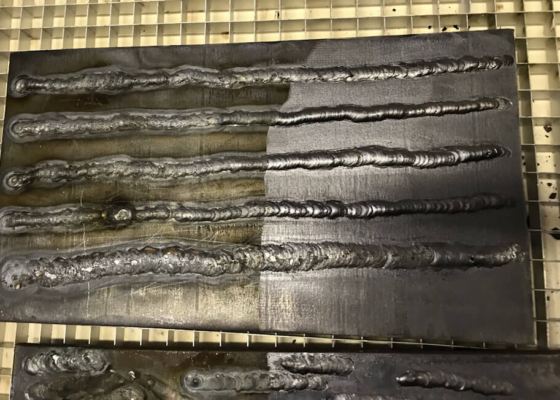

Laser ablation for maximum adhesion of ceramic coatings without environmental burden.

Read case studyLaser ablation for maximum adhesion of ceramic coatings without environmental impact.

Read case studyIn September 2018, we delivered two Thunderlaser devices to universities. The quality of these plotter lasers was also demonstrated to the staff of universities in Prague and Brno.

Read case studyFor a client in the food industry, we recently built a special machine with interchangeable tables that is used specifically for trimming and "engraving" edible paper. The marking parameters can be adjusted according to the thickness and composition of the material.

Read case studyYou might say that cleaning lasers belong only in industrial plants, but nowadays they are also commonly used in one-off, smaller applications. Saying that a laser cleans everything is slowly becoming an exaggeration. Recently, we at Narran saw this for ourselves when we took on the task of restoring an antique scale and, slowly, a vintage BMW R 80 GS motorcycle.

Read case studyCleaning lasers are truly versatile machines that can clean an industrial mould for plastic products as well as a listed building. Do you need to remove graffiti, dried gum or ordinary dirt? Take a look at examples of unconventional interventions.

Read case studyDue to the global spread of the virus, we are making every effort to ensure the safety of our customers, suppliers and employees. We are taking steps to limit the spread of the virus as much as possible, and we are working to assist and participate in new opportunities. Our machines also produce protective drapes and shields.

Read case studyDuring the injection moulding of materials (typically plastics), sprues, i.e. unwanted residues, remain on the product and need to be removed efficiently.

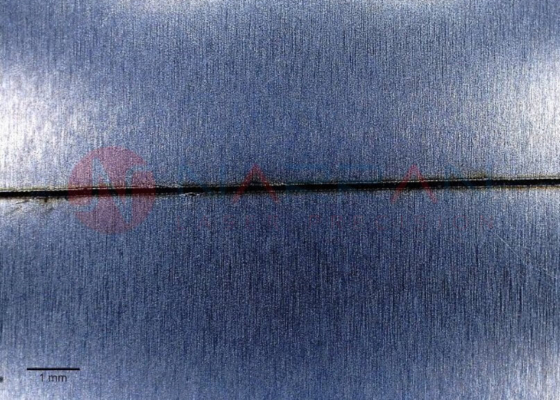

Read case studyCleaning lasers can be used for the preparation of metal materials before welding, but also for gentle cleaning of finished welds, either directly after welding or after any length of operation. The ROD mobile cleaning laser from Narran is suitable for all these applications..

Read case studyDeciding if buying a laser cleaning machine is the right choice for your business? We've put together the 10 most important points to answer your most frequently asked questions.

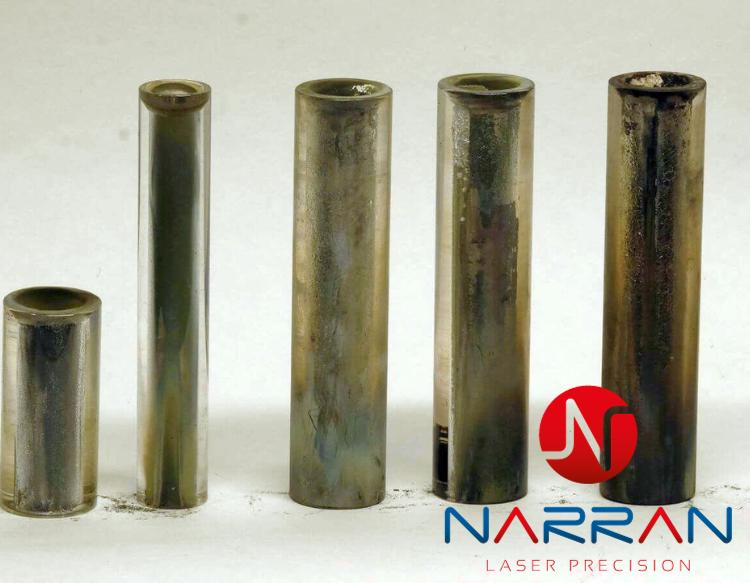

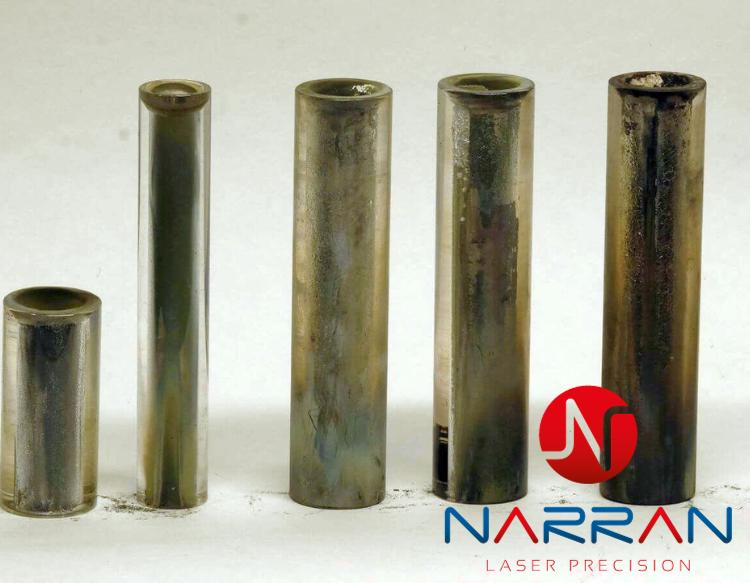

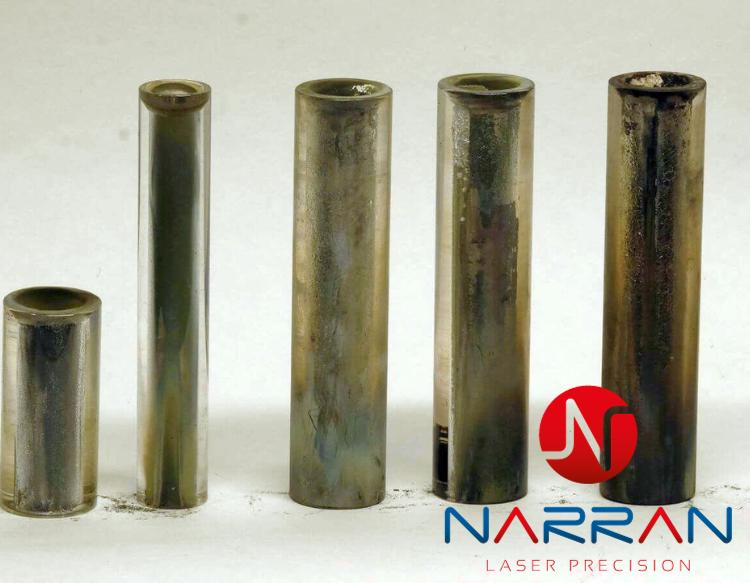

Read case studyAlthough quartz glass tubes are highly resistant to chemical changes and remain unchanged even at temperatures exceeding 2,000 °C, deposits can be effectively removed from them without damaging their surface.

Read case study

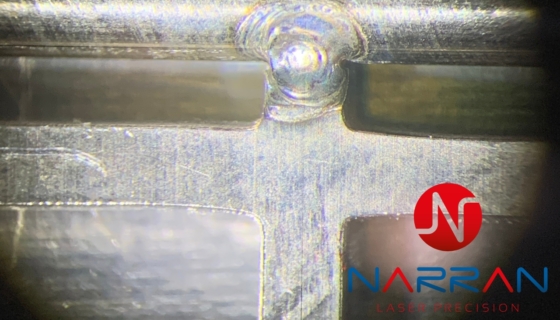

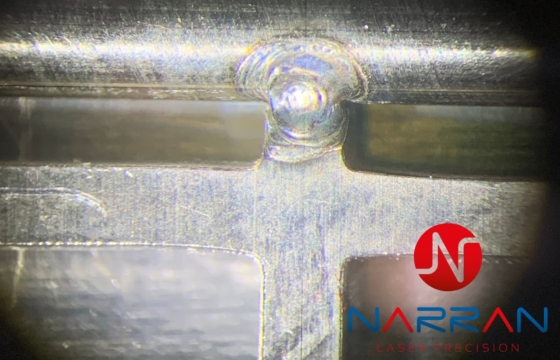

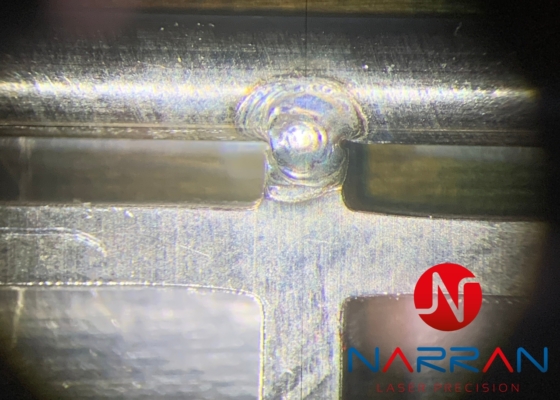

We have newly installed a SISMA SWA 150 welding laser with a peak power of 10.5 kW.

Fully automated XYZ axes ensure seamless automatic laser welding operation with and without additional material.

In the autumn of 2018, we installed a Narran Veles F20 station at Boeing's new UK manufacturing site. The customer had been using the station in the Czech Republic and had not found a competing device that suited their new location.

Read case studyWe thank the Mayor of Prague Zdeněk Hřib for the opportunity to demonstrate our technology, we appreciate it very much. We think that despite the combat conditions we were able to achieve a great result with the new type of laser without any damage to the original material.

Read case studyAlthough fibre lasers are used for working with metals, we are seeing an increasing demand for CO2 equipment for cutting thin metal foils. We have therefore started to test cutting foils on our Thunderlaser plotters.

Read case studyDemonstration of welding an A2 stainless steel antenna using the Sisma SWA 150 welding system.

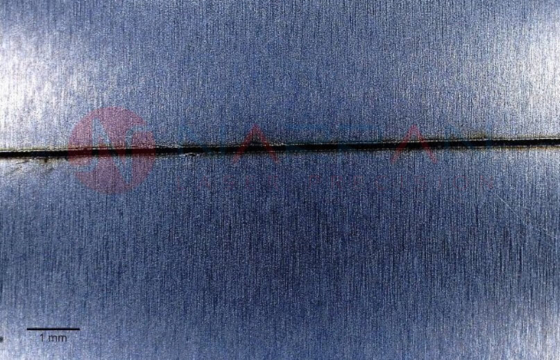

Read case studyWe have achieved exceptional accuracy and minimized deformation in testing welding 0.2 mm thick sheet metal.

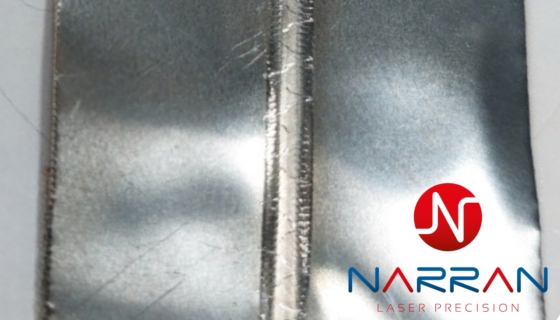

Read case studyWelding of a filter box made of 1 mm thick aluminium.

Read case studyIn this article, we focus on the specifics of laser welding of thin plates with a positioner, specifically the welding of two 2 mm thick tubes using the IPG Lightweld 1500 welding machine.

Read case studyRevitalisation of the Skoda Garde engine. Removing paint, cleaning grease and dust without disassembling the engine.

Read case studyThe laser removal of organic deposits and old paint from the steel structure is effective, meets all environmental protection requirements and does not damage the existing surface.

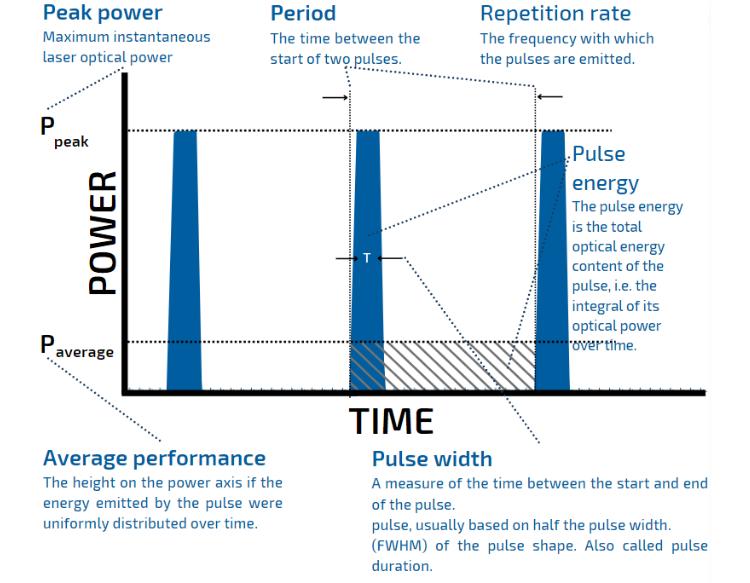

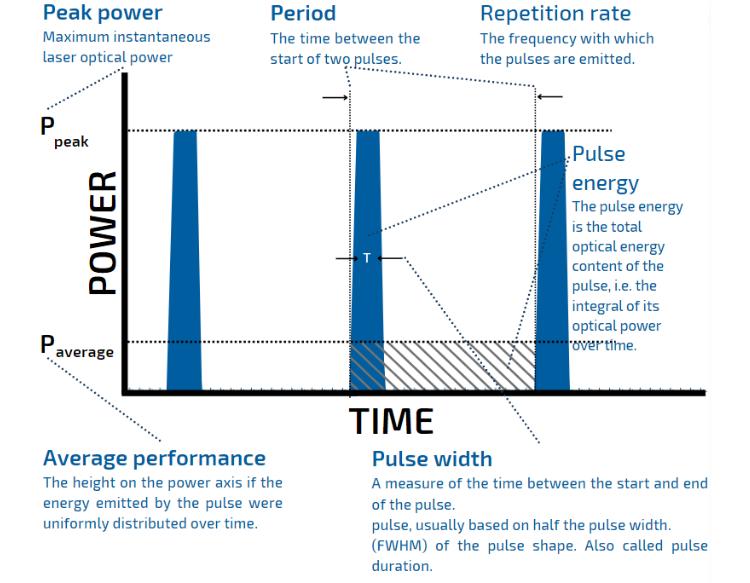

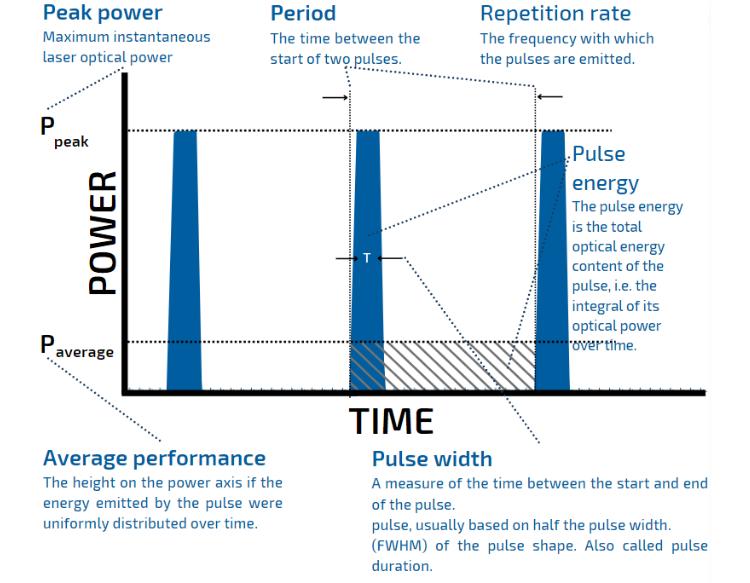

Read case studyIn this article we explain the importance of the individual parameters of cleaning lasers, the fundamental principle of laser cleaning and the applications for which each power series is suitable.

Read case studyRestoration, graffiti, dirt or soot removal, none of this is a problem for the ROD cleaning system. The laser is particularly suitable for very sensitive restoration of monuments or historical objects.

Read case studyLaser mould cleaning covers a wide range of applications, including mould presses, tyre moulds, baking moulds, injection moulds and more.

Read case studyROD cleaning lasers have countless applications and more are added every day, in this mini case-study we focus on the use of the ROD 200 in the Autochladiče Hladík company.

Read case studyUndoubtedly, the biggest advantage of ROD laser systems against other cleaning laser devices is the perfectly thought out process head, because you, as a user, will hold this very important part of the laser cleaning machine in your hand every day.

Read case studyWe believe that our lasers are the best choice for your business. In the article, we focused on several points that differentiate us from the competition.

Read case studyThe laser is not a cheap thing, the development of a laser is demanding and expensive, its production requires both a huge amount of time and money. We stand firmly behind the price of our lasers, because we know that it is not possible to drive the price lower, certainly not so that the quality or functionality of the laser does not suffer. Unfortunately, no one, not even China, has a miraculous method of manufacturing lasers, where it would be possible to produce a laser for a fraction of the price so that the quality is at least close to the products and services we provide.

Read case studyIn January of this year, we designed and delivered a unique marking custom-made Veles Fiber F30 workstation to PrusaLab – the open workshop of Josef Průša. The workstation is unique thanks to its large work area of 400x400mm. The unit was created from the ground up in our workshop in Vysočany, Prague.

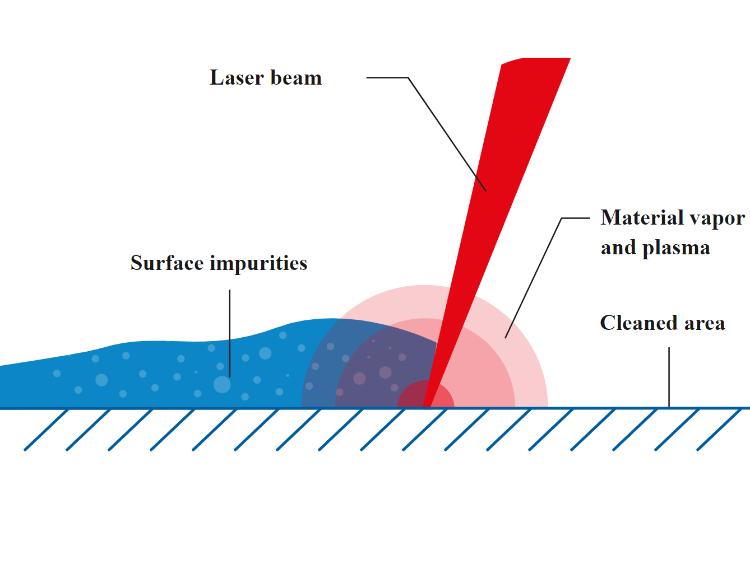

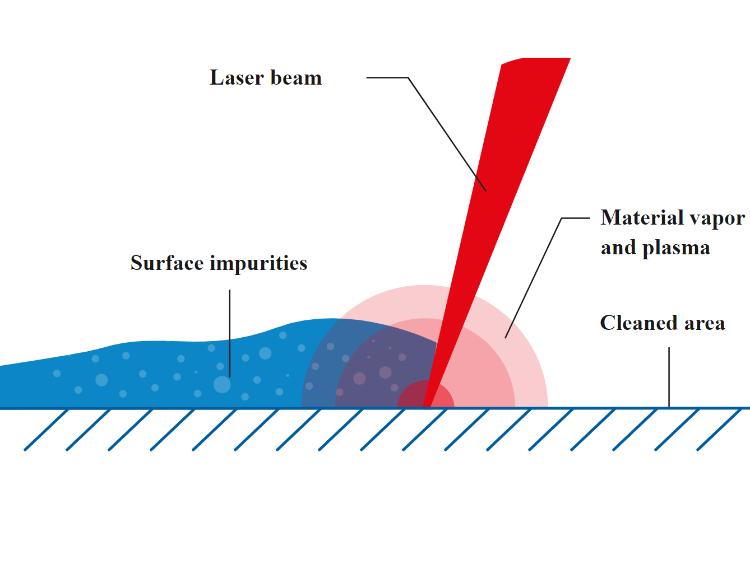

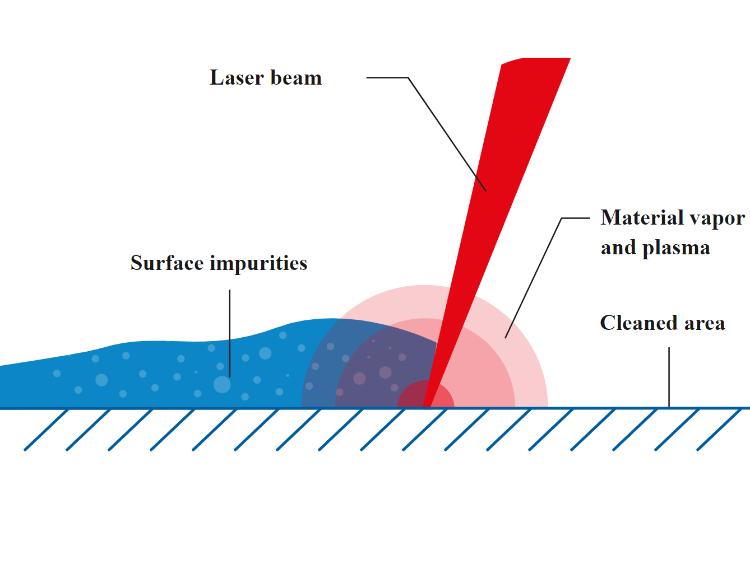

Read case studyLaser cleaning uses concentrated laser radiation to evaporate impurities from the layer. The impurities are affected by ultra-short laser pulses (μs-ms), which generate heat and heat-induced pressure - the high temperature inside the material creates a high pressure that causes it to evaporate.

Read case study

We have newly installed the SISMA SWA 150 welding laser with a peak output of 10.5 kW.

Fully automated XYZ axes ensure a trouble-free automatic laser surfacing function with and without additional material.

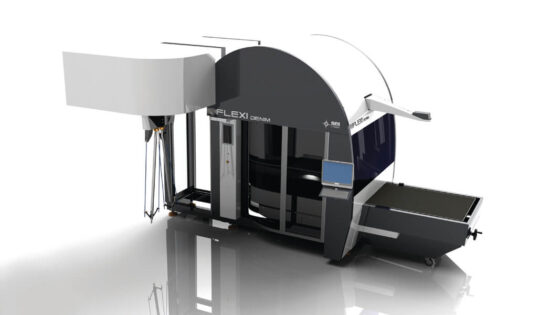

In 2019, we installed a state-of-the-art SEI flexi 600 engraving, marking and cutting laser station for Sonus, which creates graphics and promotional items.

Read case studyLGP (Light Guide Panel) light panels, also called BLU panels (Back Light Unit), are used as backlit advertising areas or lighting areas in luminaires. In the plexiglass panel, there are laser-engraved tiny dots or lines that guide the light, supplied by LEDs typically located on two or all four edges of the panel.

Read case studyOur lasers offer

Non-binding inquiry

We are also available outside normal working hours - we arrive late in the evening, on weekends or on holidays.