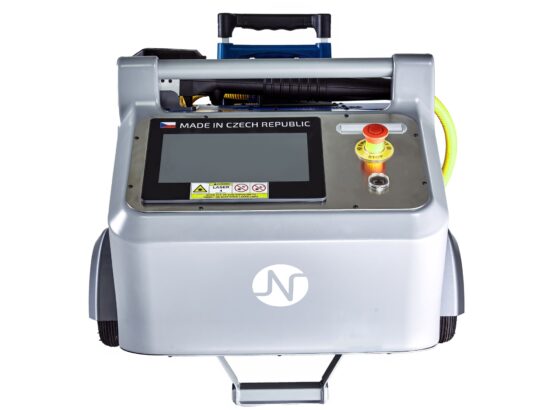

Mobile cleaning laser ROD 100W

ROD Laser is a new generation mobile industrial cleaning machine, developed and built by Narran in the Czech Republic. It is equipped with a special fiber source, which allows cleaning without damaging the surface. ROD Laser is suitable for cleaning a wide range of materials, typically metals (cleaning rust, grease, paint, etc.), but also masonry.

Suitable applications

Suitable materials

Why choose a solution from NARRAN

We can individualize our machines according to your needs

We will arrange the turnkey contract, including installation and training

We offer the possibility of testing samples at your place of operation

We will quickly supply spare parts and provide a complete service

Description

ROD Laser is a new industrial mobile cleaning machine of a new generation, manufactured and built by Narran in the Czech Republic. It is equipped with a special fiber resonator, which allows cleaning without damaging the surface. ROD Laser is suitable for cleaning a wide range of materials, typical metals (cleaning rust, grease, paint, etc.), but also masonry.

Technical Specifications:

The scanning head of the machine is suitable for manual and robotic applications, it can be mounted in industrial lines. The flexible optical fiber for guiding the laser beam enables truly mobile work and cleaning even in less accessible places. The laser requires a standard 110/230V, 50/60Hz power supply, so it can be used practically anywhere in the field. The machine is basically just a trolley with storage space for the laser head, so you can easily transport it where you need it.

The power, shape and width of the beam can be changed, even while the laser is running.

The laser has integrated air cooling, no additional cooling equipment is required.

Parameters

| Power supply | 110/230V, 50/60Hz |

| Average output power | 100 W |

| Power consumption | 500 W |

| Diode life | more than 100,000 hours |

| Optical fiber length | 5 m |

| Dimensions | 53 x 66 x 55 cm |

| Weight | 39 kg |

| Process head weight | 2,35 kg |

| Peak power | 10kW (?) |

| Power cable connector | CEE 7/7 (US: type B) |

| Operating temperature of laser / head | 5–45 °C |

| Cooling | air |

| Laser safety class | 4 |

| Wavelength | 1064 nm |

| Emission mode | pulsed, ns |

| Nominal pulse duration | 30, 60, 100, 250 ns |

| Nominal pulse energy | 0.31, 0.55, 0.91, 1.54 mJ |

| Beam scanning | 2D |

| Working distance range (focus) | 100–400 mm |

Structural and System Design

The entire system is integrated into a robust welded mobile frame, equipped with industrial wheels for easy handling and certified lifting points for use with a crane or forklift.

Standard equipment includes a flexible optical fiber (10 m as standard, up to 100 m on request), terminated with an actively cooled processing head weighing 2.5 kg, suitable for both manual operation and automated production lines.

The laser unit is powered from a standard single-phase supply (230 V, 50/60 Hz, 16 A), ensuring seamless use both in workshops and in the field.

Cooling of the entire system including the head is provided by an integrated closed water circuit with both heating and cooling functions, maintaining constant operating temperature and maximum component lifetime.

Narran ROD 500

Control System and Software Equipment

ROD 100 is equipped with an industrial Siemens PLC and an intuitive touch HMI interface for setting power, frequency, scanning patterns, and focus. The software enables:

- saving work profiles and recalling recipes,

- user access security,

- full support for OPC UA, Profinet, remote access, and logging,

- automatic focusing and beam shaping during operation,

- communication with robot systems and production lines (KUKA, ABB, UR, Stäubli).

Filtration and Fume Extraction

To ensure safe and clean operation, every Narran system is equipped with a powerful filtration unit that effectively captures dust particles and microscopic fumes generated during the laser cleaning process.

The exhaust hose can be directly connected to the processing head, enabling fume extraction right at the source. This minimizes the spread of contaminants into the surroundings and improves workplace safety.

The filtration unit uses a multi-stage air cleaning system including pre-filters, HEPA filters, and activated carbon, ensuring maximum efficiency and compliance with industrial air quality standards.

The extraction power is adjustable, allowing easy adaptation to the specific cleaning process and the type of material being removed.

Crane lifting hooks

ROD fume extraction system

Mobility and Easy Handling

The ROD series systems are designed to be quickly and safely relocated between workplaces, even within complex operations.

- Integrated certified lifting hooks allow lifting and moving the unit with a crane or forklift – ideal for work at heights or in hard-to-reach areas.

- Compact design and a durable mobile frame with industrial wheels ensure easy handling both indoors and in the field.

- Easy transport – device dimensions are optimized for quick loading into a standard van without the need for special equipment.

- Stability and safety during handling are ensured by a robust construction and well-balanced weight distribution.

Thanks to these features, the system can be easily deployed in production halls, outdoor construction sites, or service applications.

Our references

Related Products