Another use of a marking laser

Engraving and marking lasers have a myriad of different methods of using them. From the traditional ones, such as marking advertising products, through laser annealing to coloring and foaming of labels. Here is a list of other possible uses of our lasers:

Laser annealing

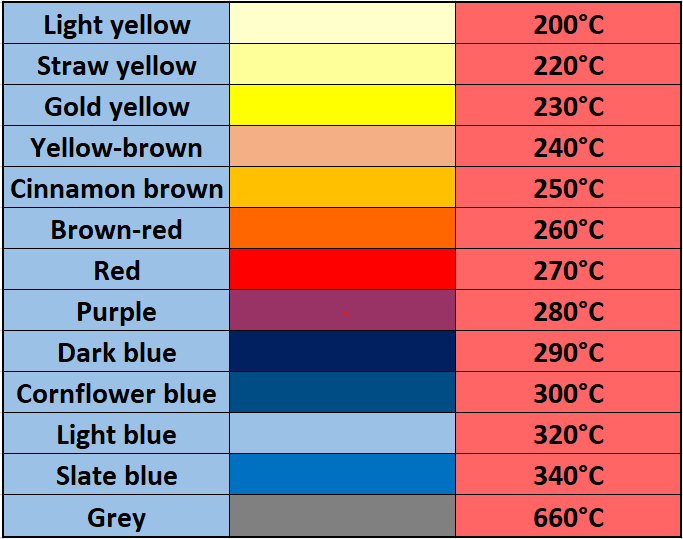

Various metals can begin to anneal in color when heated. The color of this annealing directly depends on the temperature at which the metal is heated. Annealed marks can be created using a laser beam to heat an object to a certain temperature at the place where we want to create the mark. During this process, oxidation layers begin to form on the surface of the object, creating the color appearance of the object.

Laser ablation

Coloring and foaming with laser

Laser marking is a suitable solution for marking plastic materials. Coloring and marking plastic materials in black or white is an easy task for marking laser.

Laser foaming

The laser beam can mark dark plastics and color them white, this technique is called laser foaming. The technique uses local melting of plastic. In the set area, microscopic, air-filled bubbles are formed during melting, thanks to which the plastic appears lighter than it actually is.

Laser coloring

The laser can locally color even light plastic in darker to black shades. When darkened, the laser creates microscopic particles of soot in the plastic, which settle in the plastic and then shine through the lighter plastic – the mark looks dark to black.

Marking and engraving lasers