Safety in laser cleaning: HSE Risks, measurements, and recommended controls

Laser cleaning is a highly precise method for removing corrosion, salts, and coatings without abrasive media or chemicals. From a safety perspective, however, it is not only about working with laser radiation: removing coatings generates combustion by-products and aerosol particles, and high-power systems can also involve significant noise exposure. This article summarizes key HSE risks and practical measures for safe operation based on laboratory measurements and observations from laser cleaning tests on steel prior to painting.

1) Main laser cleaning risks

1.1 Laser radiation and eye protection

Industrial lasers for surface cleaning typically fall into higher hazard classes (often Class 4). The risk is not limited to direct beam exposure—reflections and scattered radiation from metallic surfaces can also be hazardous. The foundation is a combination of engineering and administrative controls (controlled area, signage, access control) and personal protective equipment.

- Protective laser eyewear/visors must match the specific wavelength and the required attenuation level (OD).

- The workplace should be designed to minimize the risk of uncontrolled reflections (screens, barriers, appropriate layout).

- The operating regime should include functional emergency stop and clearly defined incident procedures.

Practical note: PPE is not a substitute for a controlled workplace. Without a defined zone and access control, reflection and scatter risks cannot be managed reliably.

1.2 Fumes and aerosol particles (smoke, VOCs, PAHs, isocyanates)

When removing organic coatings, thermal decomposition and combustion occur. Test measurements showed that the generated by-products contain a range of volatile and semi-volatile organic substances typical of organic-material combustion, including aromatic compounds. Some are toxic and some are classified as carcinogenic.

- VOCs and aromatics (e.g., benzene, toluene, ethylbenzene, styrene): toxic; some have proven or probable carcinogenicity.

- PAHs (polycyclic aromatic hydrocarbons): can form during incomplete combustion and are highly undesirable in terms of long-term exposure.

- Diisocyanates: detected in coatings with a polyurethane layer; risk of sensitization and respiratory damage.

From a health protection standpoint, this means that when working with coatings (especially of unknown composition), it is necessary to account for inhalation exposure to hazardous substances and design respiratory protection and ventilation/extraction accordingly.

1.3 Particles, pigments, and heavy metals

In addition to the gaseous phase, a particulate aerosol is generated, which often does not originate primarily from the steel substrate but from pigments and fillers in paints and primer layers. In practice, this means the dust composition can include elements typical of coating systems (e.g., Zn, Si, Ti, Ba). In older coatings, the presence of hazardous metals (e.g., lead) in pigmentation cannot be ruled out.

- Fine fractions (PM10/PM2.5) can penetrate deep into the lungs.

- For legacy structures (marine, industrial, bridges), consider coating identification (SDS, screening, analysis) and a conservative protection setup.

1.4 Noise during laser cleaning

Noise exposure varies significantly depending on laser type, power, and application. Measurements recorded values approximately around 104 dB for a pulsed laser (~2000 W) and typically 80–90 dB for a continuous-wave laser (~3000 W), depending on the sample and cleaning regime. Such levels require appropriate hearing protection and, in some cases, a combination of measures (double protection).

2) Extraction and filtration: A key element of exposure control

From an HSE perspective, it is critical to capture by-products as close to the source as possible. For removing coatings and contaminants, it is recommended to combine:

- Local extraction at the head (minimizing smoke spread into the work area),

- particle filtration (typically HEPA class for fine particles),

- organic gas filtration (e.g., activated-carbon stages) for VOCs and other organic components.

Did you know? Extraction efficiency is not just about fan power—it is mainly about distance. As soon as the nozzle moves away from the emission source, capture efficiency drops sharply. At a distance comparable to the nozzle diameter, efficiency can decrease by tens of percent.

This is why we developed an adjustable sliding nozzle system: it allows precise distance setting for each application and keeps extraction exactly where it belongs—directly at the source.

Warning: If extraction cannot be connected directly to the head, or filtration is sized only for coarse particles, the likelihood of exposure to harmful substances in the operator’s breathing zone increases. For coatings with a PU component (isocyanates) and for unknown systems, it is advisable to proceed conservatively and prioritize robust filtration and controlled ventilation.

With Narran systems, the safety architecture (work zone, local extraction capability, filtration selection, and recommended PPE) is addressed as part of the overall application concept—not as an “add-on” at the end. The specific configuration is always selected according to the type of layer being removed, the environment (workshop / outdoors / enclosed space), and the required productivity.

3) Recommended personal protective equipment (PPE)

- Eye/face protection: laser safety glasses or a face shield matching the wavelength and power class of the system; in practice, often combined with mechanical protection against particles.

- Respiratory protection: at minimum, P3-class particulate filters for fine aerosol; for coating removal, recommend a solution that also addresses organic components (based on risks and local conditions).

- Hearing protection: industrial earmuffs; for higher noise levels, consider double protection (earplugs + earmuffs).

- Skin protection: workwear with sufficient coverage; gloves according to the application (heat, mechanical resistance, part handling).

4) Process safety: how to prevent substrate damage

Safe laser cleaning also includes “result safety.” Tests showed that the combination of high power and low travel speed can lead to surface oxidation and localized melting. For steel prior to painting, it is also important to maintain the required surface roughness profile: with improper settings, a high-power continuous-wave laser can reduce the blast profile and thus affect coating adhesion.

- Always verify parameter settings on a test area (material, coating, speed, overlap, distance).

- Avoid “dwelling” the beam in one spot; implement process rules for travel speed.

- For critical applications, check not only visual cleanliness but also the surface profile per painting requirements.

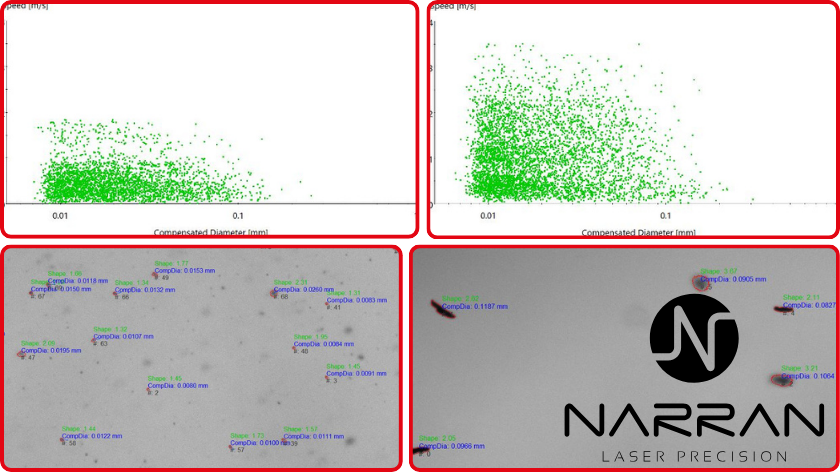

5) Measurement capabilities: simultaneous particle aizing and velocimetry

In addition to standard safety recommendations, we are able to perform combined particle size–velocity analysis during laser cleaning in our internal laboratory environment. Using high-speed shadow imaging (ShadowSizing), we measure particle diameter, shape factor and individual particle velocity simultaneously for each detected particle.

For these measurements, we use technology from Dantec Dynamics, which enables time-resolved imaging and precise evaluation of particle behavior directly in the cleaning plume. This allows us to base safety decisions on real, application-specific data rather than assumptions.

The results can be used for inhalation risk assessment, validation of extraction and filtration concepts, optimization of air-knife and purge systems for optics protection, and as technical input for workplace safety audits and documentation.

In short: we do not assume how particles behave during laser cleaning. We measure it – and design controls accordingly.

6) Recommended procedure (SOP) for safe laser cleaning

- Identify the layer and risks (rust / salt / coating / PU / unknown composition).

- Workplace design: define the controlled zone, signage, entry control, emergency stop.

- Extraction and filtration: local extraction point at the head, particle + organic filtration according to the application.

- PPE: eyes/face (laser), respiratory, hearing, skin.

- Test area: verify parameters and visual outcome; for painting, also verify the surface profile.

- Operation: maintain travel speed, check smoke in the breathing zone, monitor noise and exposure limits.

- Documentation: record parameters, material, and conditions; maintain filtration units and replace filters based on loading.

Pre-Start Control Checklist

- Is the controlled laser zone defined and marked, and is access control ensured?

- Is extraction functional and is the filtration correctly selected (particles + organics for the application)?

- Are the correct laser glasses/visor used for the given wavelength?

- Is respiratory protection adequate for the layer type (especially coatings, PU)?

- Is hearing protection addressed (based on expected noise level)?

- Has a test area been performed and has the resulting surface condition been verified?

7) Why safety should be addressed systemically

Safe laser-cleaning operation is a combination of controlled laser-zone management, PPE selection, effective extraction and filtration, and correct process settings to prevent excessive oxidation or substrate melting. This is doubly true when removing organic coatings, where combustion by-products and aerosol particles are the primary source of health risk.