Advantages:

- Easy touch screen operation

- smooth, shiny and straight edge after trimming

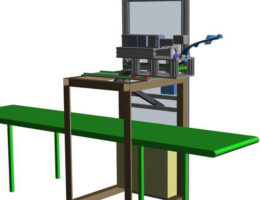

- easy loading and unloading of products

- automatic recognition of the parts to be filed

- two working areas – loading and working

- cutting speed up to 100 cm/min

- easy data import via Ethernet, USB or SD card

- possibility to cut multiple products at once

- complete covering – laser class 1

- possibility to cut any shape at an angle

- cutting and repeat accuracy 0.005mm