Merry Christmas

and a Happy New Year!

Thank you for your trust and cooperation throughout the past year.

We wish you good health, success, and all the best in the year ahead.

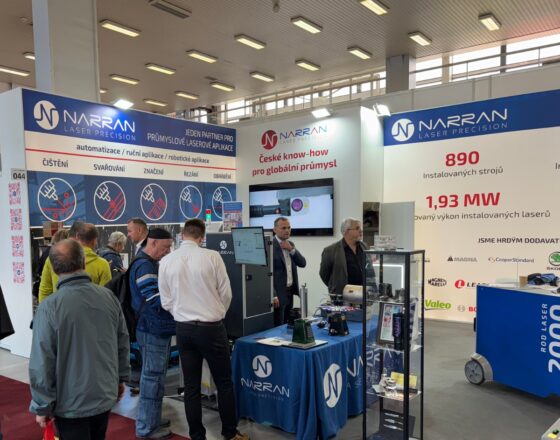

The year 2025 was for Narran primarily about real-world deployment of laser technologies in demanding operational environments. We participated in unique projects in the nuclear energy sector, brought our own patented technical solution into practical use, and presented our systems to the professional community at key industrial trade fairs and conferences across Europe, the USA, and Asia.

Unique Project: Cleaning of the Reactor Pressure Vessel at Temelín Nuclear Power Plant

The Narran ROD 300 AIR laser cleaning system was successfully deployed in a unique project at the Temelín Nuclear Power Plant, in cooperation with our strategic partner ŠKODA JS.

The project focused on cleaning the reactor pressure vessel (RPV) and adjacent floor areas during a scheduled outage. The task was particularly demanding due to confined spaces and the requirement for safe remote operation. Prior to implementation, several cleaning methods were tested, with laser cleaning selected as one of the most effective and stable solutions.

This marks the second successful reference at the Temelín Nuclear Power Plant. Following a previous project in which Narran laser systems were used to clean the RPV support ring, our technology was once again deployed directly within a nuclear power plant environment, delivering excellent results.

WoGaWe (Wobble-Gap-Welding) – Patented Hybrid Welding Technology

WoGaWe is a patented hybrid welding technology developed by us that combines an oscillation-controlled laser beam with GMAW arc welding (CMT).

The principle is based on a deliberately created narrow gap between the welded parts, whose sidewalls are preheated by a wobbling laser beam with an effect comparable to keyhole welding.

Filler material melted by the arc is subsequently drawn into the gap by capillary forces, resulting in homogeneous weld filling.

The technology enables single-pass welding of thicknesses up to approximately 5–6 mm, achieving full penetration, uniform microstructure, and a stable weld root at

processing speeds typical of laser welding.

Thanks to controlled filler material transfer, the method is also suitable for

welding dissimilar materials using transition filler wires.

WoGaWe is designed for robotic and automated applications in the energy sector, pressure vessel manufacturing, heat exchanger production, and general mechanical engineering.