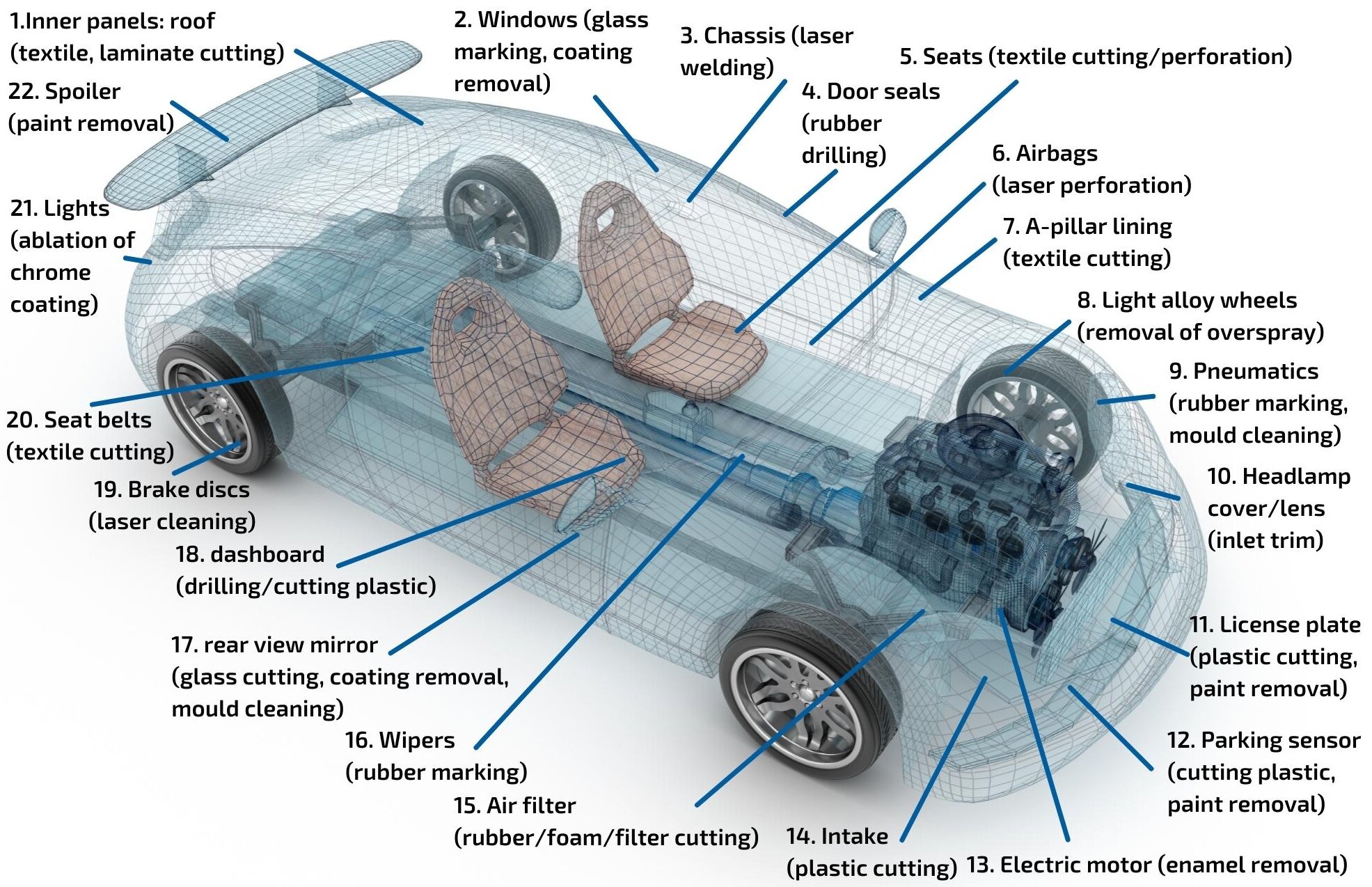

CO2 and fiber lasers are inherently among the most versatile tools in the automotive industry, mainly due to their ability to process a wide range of materials including plastics, metals, textiles, glass, rubber, but also less conventional materials in the automotive industry such as wood, leather or carbon fiber. Laser-processed components can therefore be found in all parts of the vehicle, both interior and exterior.

Fiber and CO2 lasers have a wide range of output powers from units of watts to tens of kilowatts, and each system is used in a variety of processes. While the lower power systems are mainly used for marking and engraving, the high power systems provide high quality cutting, cleaning and welding.

Laser processing of plastics

Lasers are used in the processing of plastic parts, examples of specific applications include bumpers, pillars, spoilers, trims, interior panels and dashboards, license plates and light covers. A wide range of plastics are used:

- Acrylonitrile butadiene styrene (ABS)

- Thermoplastic polyolefin (TPO)

- Polypropylene

- Polycarbonate

- High-density polyethylene (HDPE)

- Composite and laminate

Plastics can be uncoated or painted and combined with other materials – for example, fabric-covered interior columns, composite or veneered cladding panels, and carbon or glass fiber-filled support structures for reinforcement.

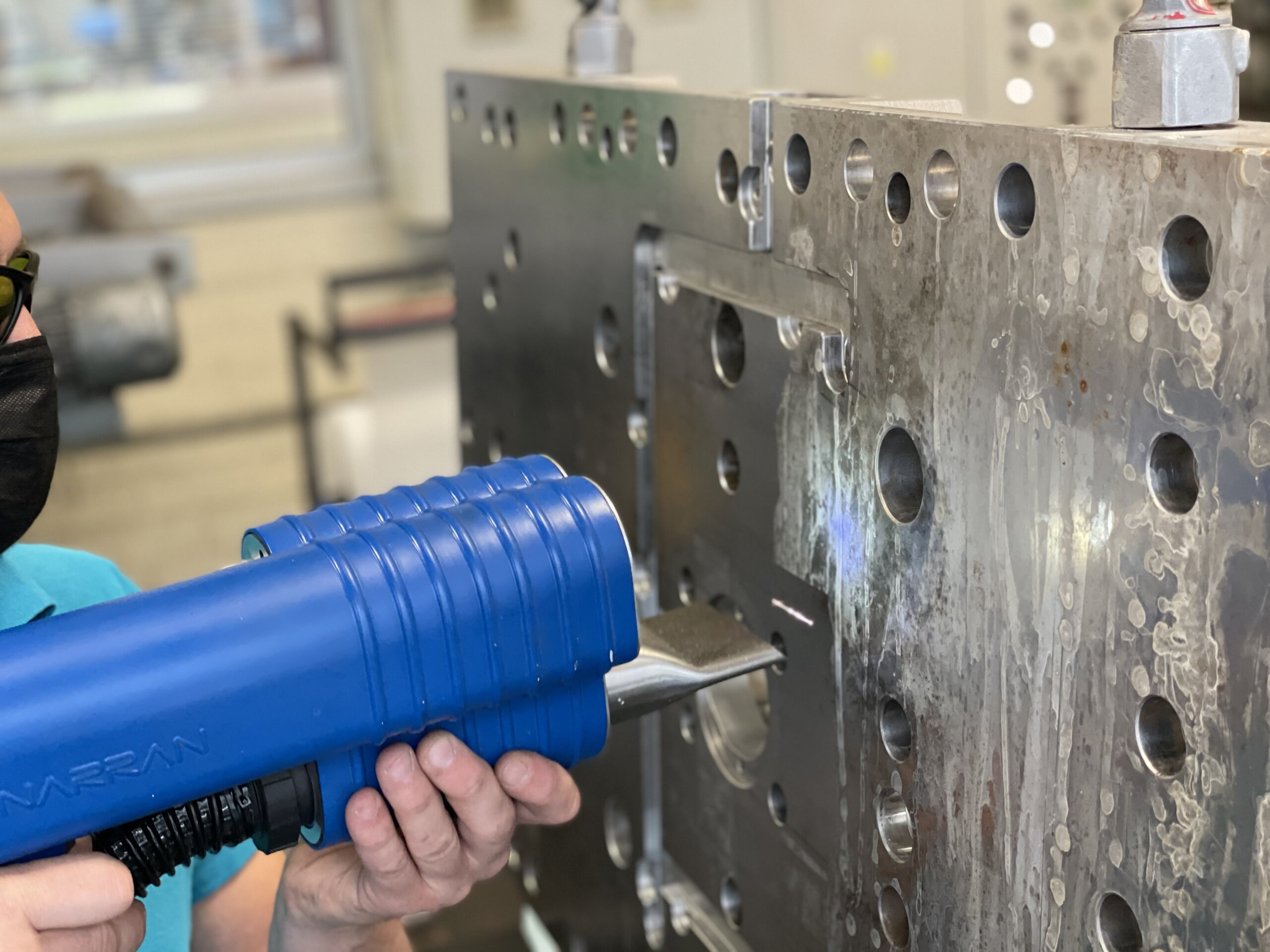

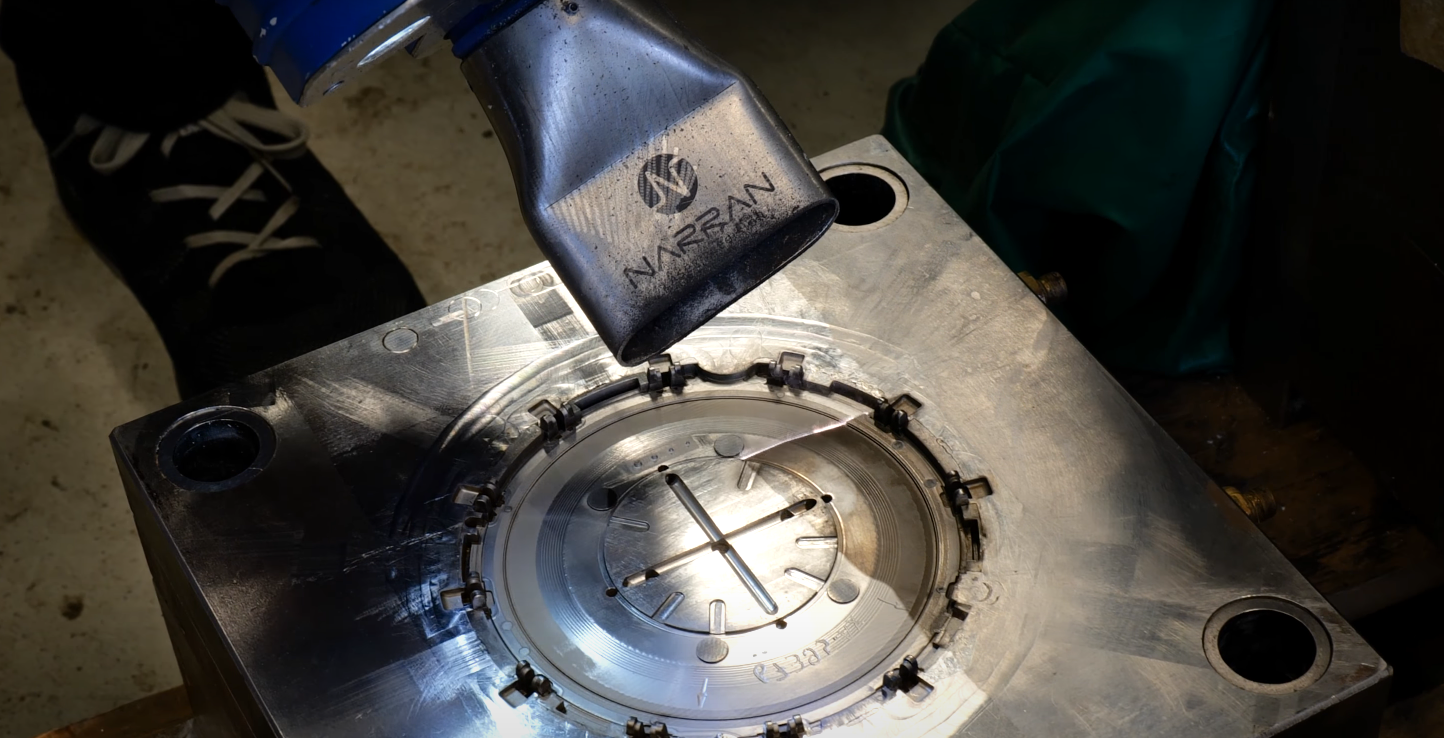

Fiber laser cleaning systems are also widely used to repair and clean injection molds for plastic parts. The primary reason for the growth in popularity of cleaning lasers over chemical or abrasive cleaning lies in the gentleness, associated high process repeatability, low operating costs, significantly higher system mobility, environmental friendliness and the absence of the need to work with contaminated waste/cleaning media.

Lasers can be used to cut or drill holes for mounting points, lights, switches, parking sensors and other components, as well as to degrade or trim excess plastic left over from the injection molding process (see laser sprue cutting station). Headlight housings and lenses made of clear plastic often require laser trimming to remove the protrusions of waste plastic left after injection molding.

Plastic cutting operations are typically carried out with laser power from 80W upwards, depending on the time available to complete the task; our Narran OEM Veles series are suitable for these applications. When assessing the total cycle time for a set of operations, handling time must be taken into account so that laser power can be selected accordingly. Of course, handling requirements can be complex and cutting operations often require three-dimensional movement of the laser beam or part.

Surface cleaning/texturing

Laser technologies are not only used in the automotive industry for cutting, drilling and trimming. Laser ablation also offers several applications in automotive manufacturing. Examples include surface treatment or removal of paint, rust and other unwanted surfaces from selected areas of metals or composite, and it also finds use in cleaning injection molds and parts. This is often necessary when a part is to be adhesively bonded to a painted surface; it may be necessary to remove the top coat of paint or roughen the surface to promote good adhesion.

The cleaning lasers also achieve high efficiency in surface preparation for welding, soldering, painting and cleaning of finished welds. The laser delivers just enough energy to remove the unwanted surface without damaging the material. Precise geometries can be easily realized, controlling ablation depth and surface texture, and changing ablation patterns as needed with minimal effort.