Laser cleaning: key phase before applying ceramic anti-corrosion system

Laser ablation for maximum adhesion of ceramic coatings without environmental burden.

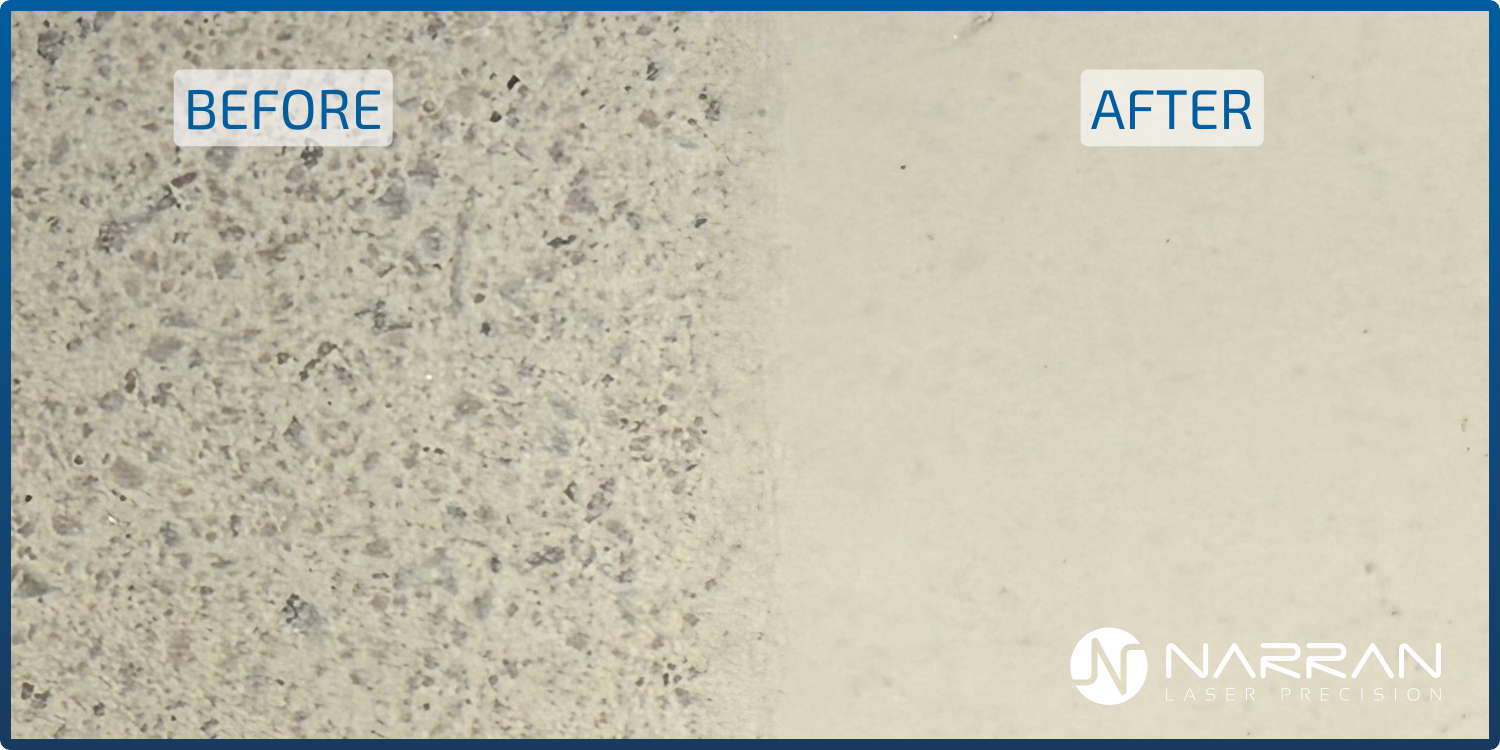

In response to the growing demand for environmentally friendly and highly durable methods of protecting steel and concrete surfaces, we conducted a comprehensive experimental series to verify the effectiveness of laser cleaning as a primary surface preparation method. The goal was to optimize the adhesion and chemical bonding of an advanced ceramic anti-corrosion system that directly bonds to the active substrate center of the material.

Initial Problem

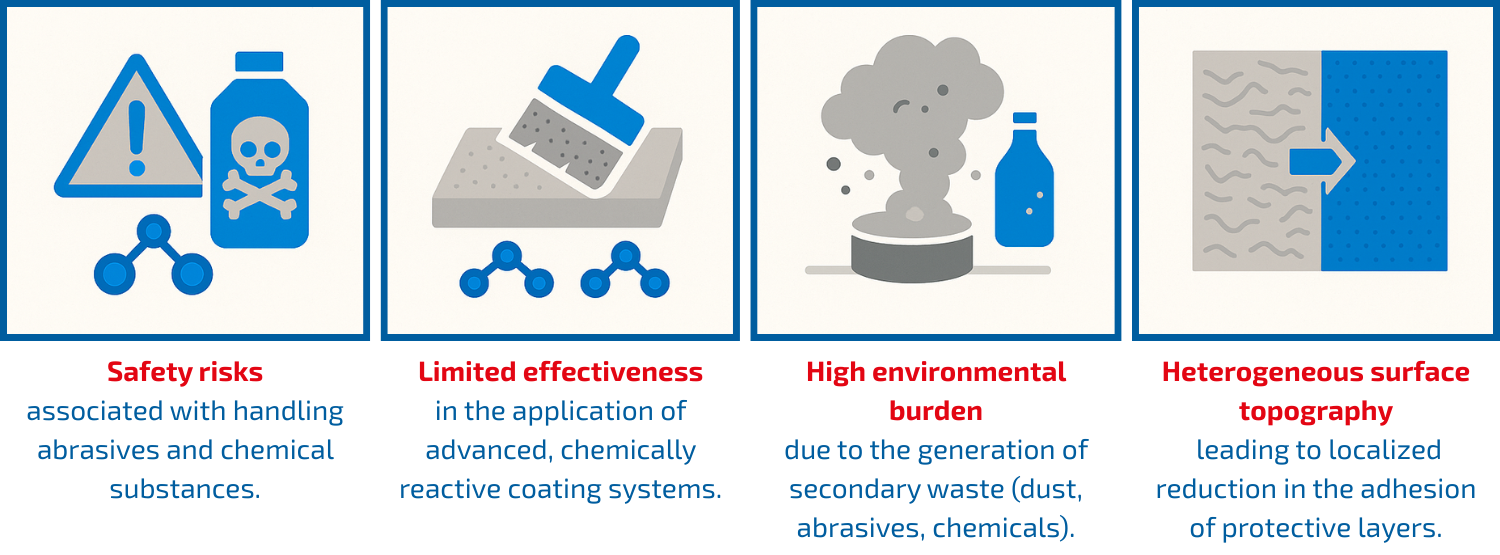

Conventional surface preparation methods, including abrasive blasting (sandblasting), chemical decontamination, or mechanical grinding, exhibit several significant disadvantages:

There was a need to introduce an alternative process that allows for highly controlled surface preparation without generating secondary contamination.

Applied Technology

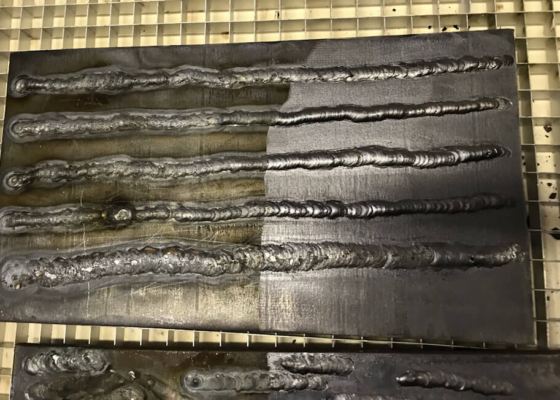

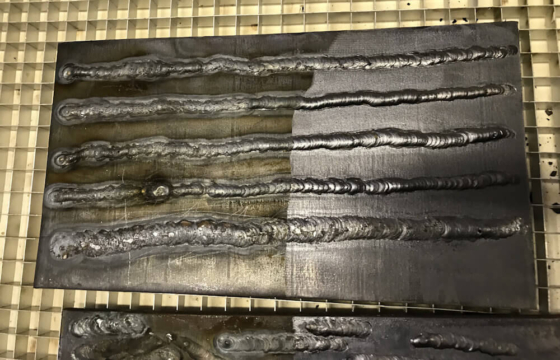

Laser cleaning was optimized to achieve the desired microstructure of the surface—removal of corrosion products, oxide layers, and organic contaminants while simultaneously creating a finely roughened morphology necessary for subsequent chemical interaction with the ceramic system.

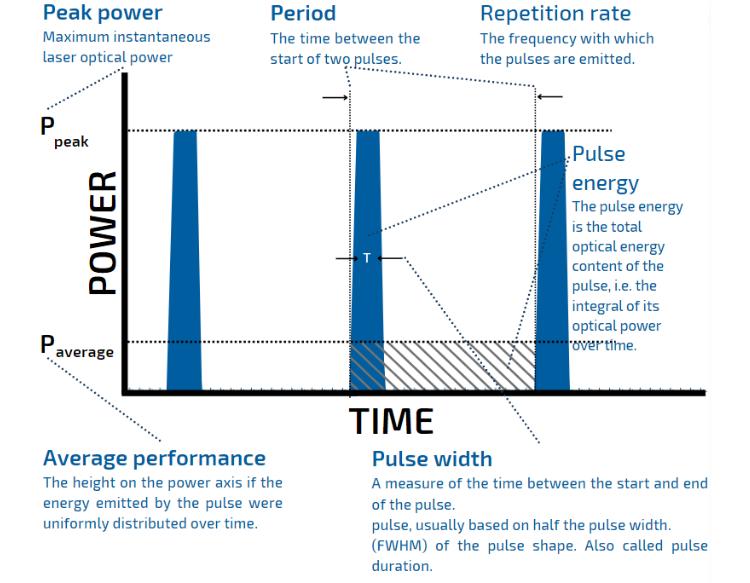

The process mechanism involved the ablation of contaminants through photothermal and photomechanical interaction of the laser pulse with the surface layer, leaving the substrate unaffected.

For the project we used a pulsed ROD 500 laser system with the following parameters:

| Average power | 500 W |

| Pulse energy | 100 mJ |

| Pulse duration | 100-150 ns |

| Wavelength | 1064 nm |

Results

Using scanning electron microscopy (SEM) and profilometric analysis, it was demonstrated:

-

Increase in average surface roughness (Ra) by 38% compared to mechanical grinding.

-

Removal of 100% of corrosion layers and organic contaminants without overheating the substrate.

-

Increase in adhesion of the ceramic system (measured by pull-off test according to ASTM D4541) by up to 32% compared to abrasive cleaning.

-

Reduction of environmental contamination by more than 90% compared to blasting methods.

Thermographic measurements during the process confirmed that the substrate temperature did not exceed the critical threshold of 150 °C, thereby eliminating the risk of thermal alteration of the material’s microstructure.

Discussion

Laser cleaning offers a unique combination of selectivity, precision, and environmental safety. In the case of surface preparation for the application of ceramic anti-corrosion layers, it is crucial to:

-

Create a homogeneous, activated, and slightly roughened surface structure.

-

Minimize the risk of introducing new contaminants.

-

Preserve the integrity of the base material (especially the absence of microcracks or thermal damage).

Therefore, laser technology is a suitable choice not only for common industrial applications but also for extremely demanding environments, such as nuclear energy, petrochemicals, or aerospace.

Conclusion

The results demonstrated that the use of the pulsed laser system ROD 500 in surface preparation significantly increases the effectiveness of the subsequent application of ceramic anti-corrosion systems.

Laser cleaning enables:

-

Precise removal of contaminants without damaging the substrate.

-

Significant increase in adhesion of protective layers.

-

Elimination of secondary environmental burden.

-

Simplification of safety protocols in the workplace.

This method proves to be a promising choice for modern industrial processes requiring maximum reliability and long-term protection of materials.

Related machines