Laser cleaning of quartz glass

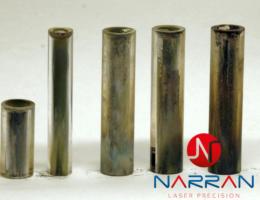

Efficient cleaning of glass tubes using laser technology

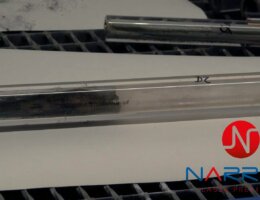

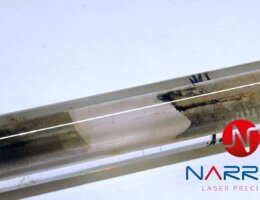

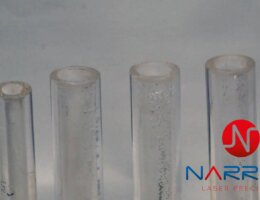

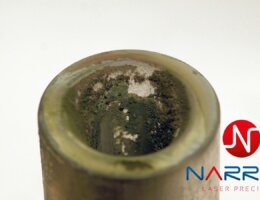

The laser cleaning of glass tubes in this case involves the removal of both organic and inorganic substances. In the manufacturing process, the stainless steel tubes are subjected to high temperatures in excess of 1000 °C by induction heating while surrounded by a protective atmosphere of hydrogen. This protective atmosphere is maintained by passing the stainless steel tubes through quartz glass tubes. Residues of mineral oils and evaporated metals lead to the formation of deposits on the inner surface of the quartz glass tubes. These deposits contribute to surface defects on the stainless steel tubes produced.

Although quartz glass tubes are highly resistant to chemical changes and remain unchanged even at temperatures exceeding 2 000 °C, the deposits can be effectively removed without damaging the surface. The removal process involves the use of a pulsed laser followed by a chemical rinse. The cost of this cleaning method ranges from approximately EUR 6 to EUR 20, depending on the size of the tubes and the extent of the contamination.

We would like to thank our customer providing laser cleaning services for providing the case study Lsrservices.