Laser mold cleaning covers a wide range of applications including press molds, tyre molds, baking molds, injection molds and more.

In addition, the laser solution enables mold cleaning without the need to disassemble and move the mold. Under certain circumstances, our cleaning systems can even perform work at the mold’s operating temperatures, so there is no disassembly/reassembly or cooling/warming period required after cleaning is complete – minimizing the time lost in mold shutdown.

HOW LASER MOLD CLEANING WORKS

Laser cleaning (laser ablation) – uses thousands of laser pulses per second to absorb impurities and remove them (vaporization) from the substrate without damaging the base material. With no additional waste and little or no risk when used properly, laser systems are ideal for cleaning various types of molds. Laser cleaning has consistent quality and operating life of up to hundreds of thousands of cleaning hours – making it a cost-effective solution for cleaning metals and non-metals.

ADVANTAGES OF LASER MOLD CLEANING

Laser mold cleaning has several advantages. The most common include:

LASER CLEANING OF COMPOSITE MOLDS

Laser cleaning technology is particularly effective in cleaning large molds/tools used for the production of carbon fibre/glass reinforced plastic composite CFRP/GRP. Current research shows that molds made of nickel, steel, aluminium and high-strength steel can be cleaned efficiently by laser without damaging the base material.

The method is currently being promoted as the most cost-effective mold cleaning option in the aerospace industry. Compared to, for example, ice pellet blasting, laser cleaning is significantly easier to automate, very quiet and up to 15 times faster. In addition, the laser method takes place without the need to clean process and abrasive residues.

CLEANING OF GLASS MOLDS

Glass molds have very specific cleaning requirements. The most important problems in cleaning molds include:

-

- There should be no increase in the volume of, for example, bottles. For this reason, the base material must not be affected.

- The sealing edges must be maintained to avoid burrs.

- Many small openings can be found in glass molds to allow air to enter. Laser cleaning will ensure that these openings are well cleaned and, of course, no residues remain.

LASER CLEANING OF INVAR

Molds made from INVAR, nickel, steel, aluminium and high-strength steel can be effectively laser cleaned without damaging the base material.

Our systems are not only efficient, but this technology is also the most cost-effective and one of the fastest alternatives for mold cleaning in the aerospace industry.

CLEANING OF INJECTION MOLDS

Laser mold cleaning is an excellent way to clean and sterilise molds as it allows you to clean molds at source – without the need to dismantle parts, waste time in transit and risk damage. In addition, if we have a large enough opening, cleaning can be carried out at operating temperatures, which means that no cooling time is required, reducing the amount of machine downtime required.

The solution can be either manual or automated – whichever works best depends on your operational needs.

LASER CLEANING OF TYRE MOLDS

Tyre molds are an important part of the car manufacturing process. However, after a few days of use, impurities can start to build up on the molds. This not only destroys the tire’s finish, but can slow down the manufacturing process. Laser cleaning helps to remove dirt without damaging the molds’ substrate, so you can streamline tire production while extending the life of your product. Laser cleaning solutions range from manual to automated options:

- Flexibility of use for different mold geometries and profiles.

- Lower operating costs – compared to media blasting options.

- A noiseless alternative that won’t damage your mold.

- An easy-to-use solution where space is limited.

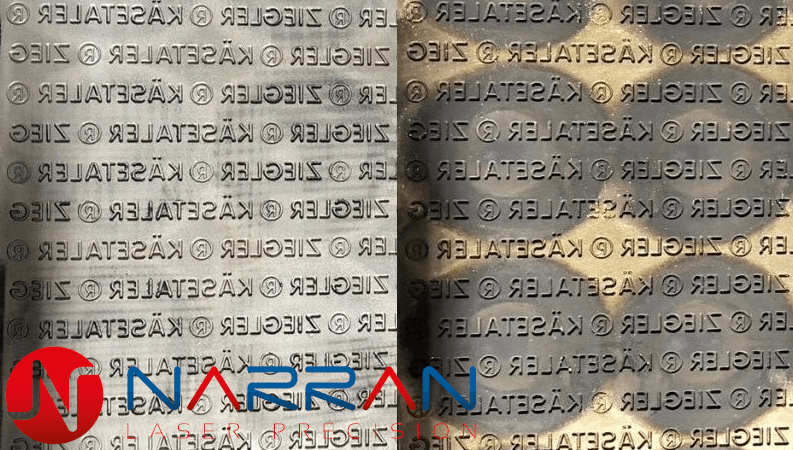

LASER CLEANING OF PVD TOOLS

PVD (Plasma Vapor Deposition) coating applications are becoming increasingly important in modern surface treatment technology. During the process, however, the applied coating not only adheres to the target surface, but also collects on surrounding materials, including the tools and fixtures used to hold the parts in the reaction chamber.

Over time, excess PVD coating materials lead to undesirable effects such as reduced tolerance of workpieces with poor chamber sealing, resulting in increased moisture and increased heating time.