Are you deciding whether the purchase of a cleaning laser is the right choice for your business? We have put together the 10 most important points that will answer your most frequently asked questions.

1. Lowest operating costs from all cleaning methods

Our lasers can clean 24/7 with operating costs being lower than 1EUR for an hour of cleaning. Unlike sandblasting or waterjet cleaning, it doesn’t require production to stop.

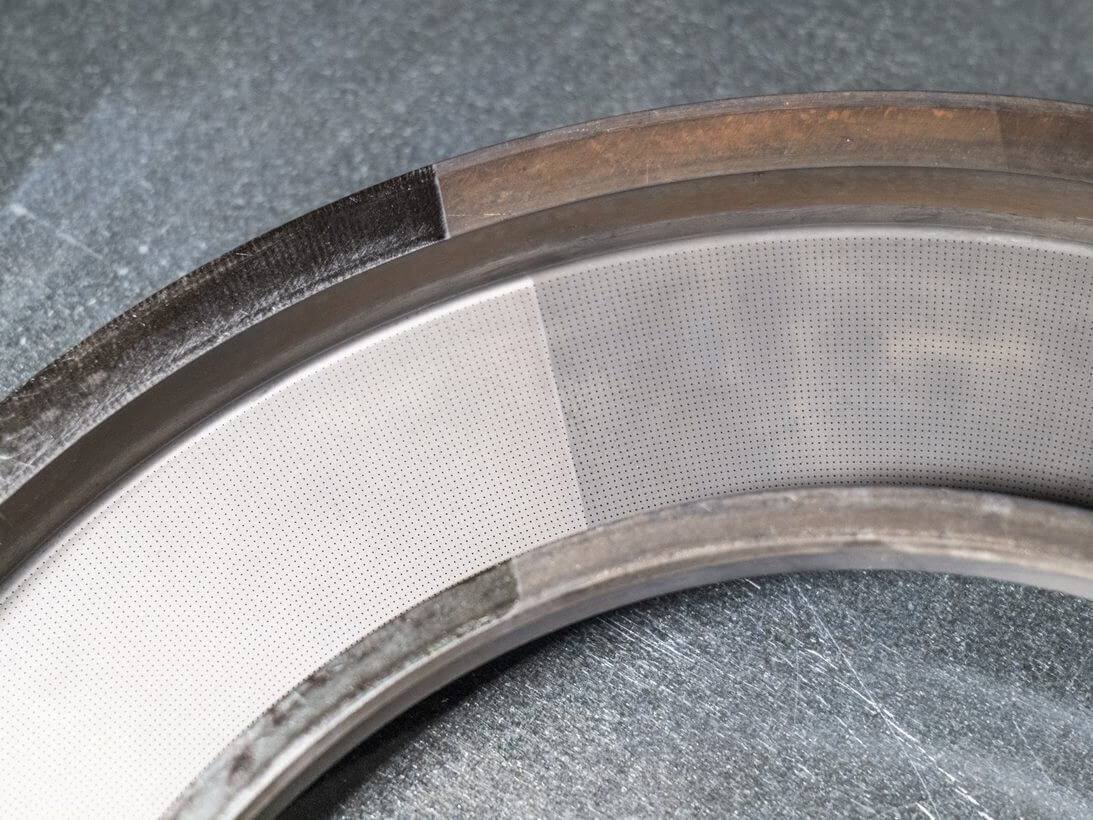

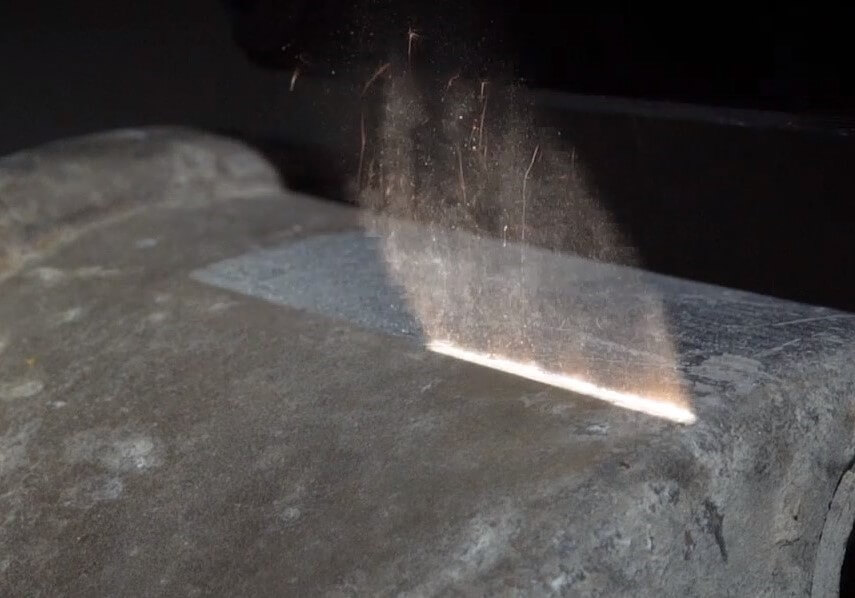

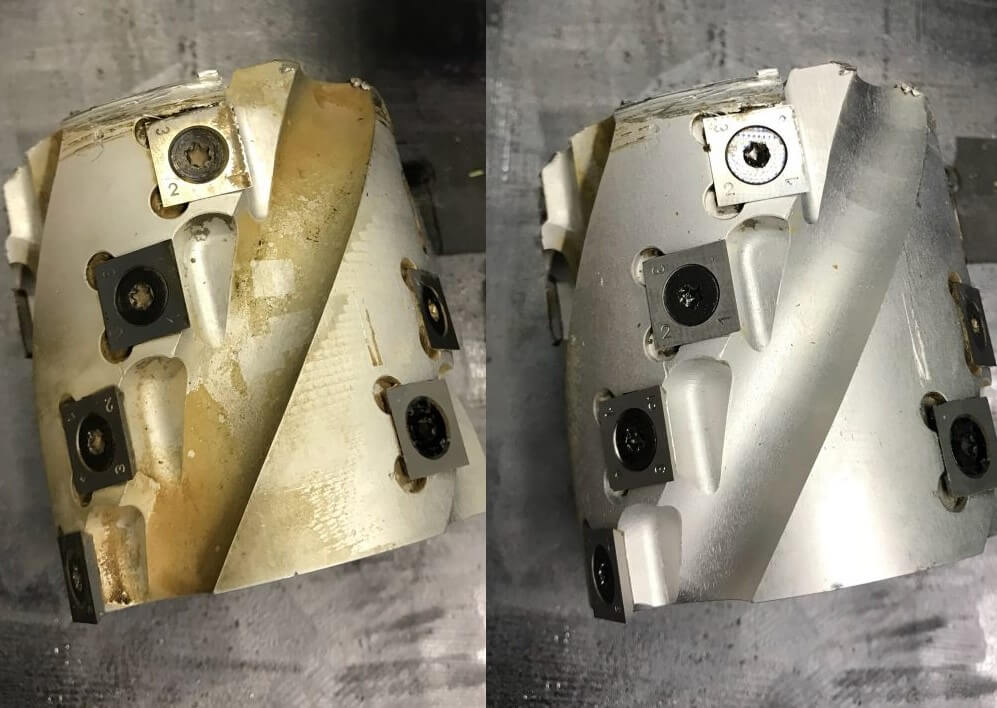

2. No damage to the underlying material

Laser cleaning is a very gentle process that destroys any unwanted coating, yet leaves the underlying material intact and undamaged

3. Countless applications

Our laser can be used for cleaning a huge scale of undesirable surfaces, most common being fats, separators, rust and oxidation, paint, ink, oil, dried polyurethane foam, lacquers and adhesives, natural and synthetic rubbers, grease.

4. Minimal temperature influence on the underlying material

Laser cleaning is a non-contact, non-abrasive method that is very gentle on the underlying surface of the material.

5. All of our lasers are mobile

The whole process of loading, unloading laser into a car, and preparing it for cleaning takes approximately 10-15 minutes. Our lasers are ready to get into action quickly.

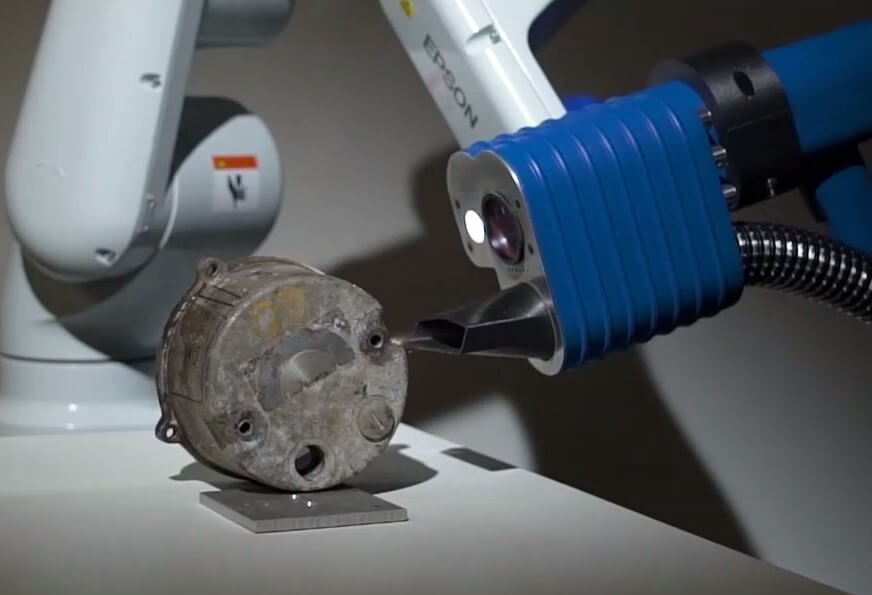

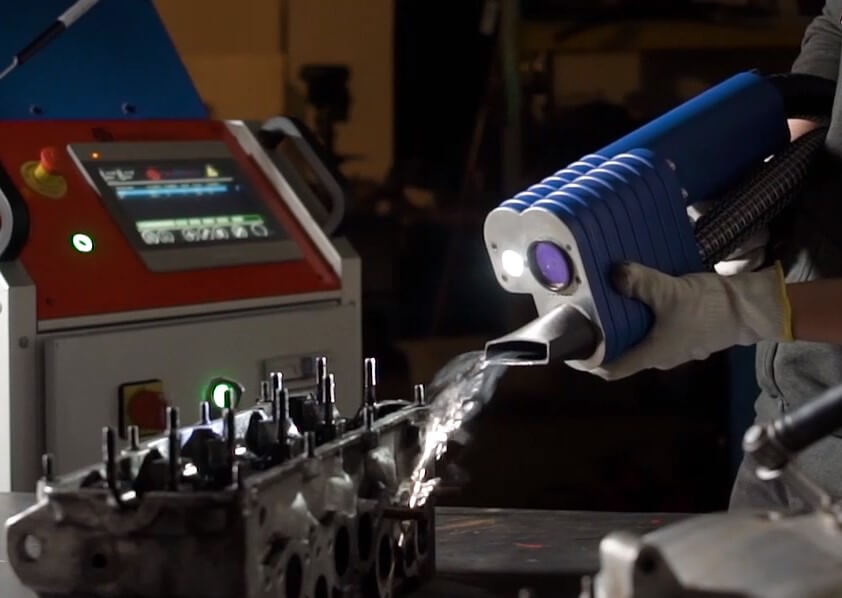

6. Handheld, robotic, integrated into the production line

Our goal is to perfectly fulfill the needs of your business, our lasers can be handheld, equipped with a robotic arm, or integrated straight into the production line without it needing to stop.

7. Ergonomic, easy to manipulate laser head

Our brand new handheld cleaning head is the result of over 6 years of development and thousands of hours of cleaning experience. It is light, practical, ergonomic, and easy to manipulate.

8. Laser cleaning is green

Compared to conventional cleaning methods, almost no waste material is produced by laser cleaning because most of the impurities evaporate. Another flaw that makes this method ecological is the minimal energy consumption.

9. Testing in advance

Upon agreement, you can test our machines both at our offices in the Czech Republic or we can simply take the laser to your place, wherever it is. You can also just send us the samples and we will report the cleaning results to you.

10. Laser cleaning technology is a rapidly growing industry

According to researchandmarkets.com, the laser cleaning market was valued at USD 588.8 Million in 2018 and is expected to reach USD 723.9 Million by 2023, at a CAGR of 4.22%