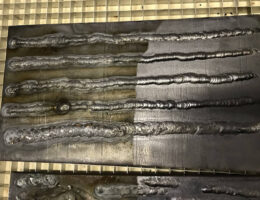

Laser cleaning of welds

The quality of the weld is greatly influenced by the cleanliness of the parts being welded. Lasers can effectively remove both the oxide layer formed during corrosion (rust), as well as grease, paint residues or anticorrosive products. However, the cleaning laser is also suitable for cleaning already finished welds, whether on stainless steel or classic welds on structural steel. The laser removes unwanted discolouration, oxidation layer and other impurities from the weld. Unlike traditional methods, it does not damage the weld or leave grooves.

In the automotive industry, the laser is used to clean welds before painting. In the chemical industry, we have recently carried out quality control tests on welds of large volume chemical tanks where other methods such as dry ice cleaning or electrolysis cleaning have failed.