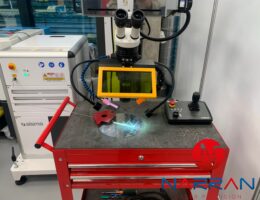

Antenna welding with Sisma SWA 150 laser welder

Laser welding is a cutting-edge technology that enables high precision and quality welds, even for complex projects. In this case, we are focusing on the welding of an A2 stainless steel antenna that was created by combining laser cut parts.

Project description

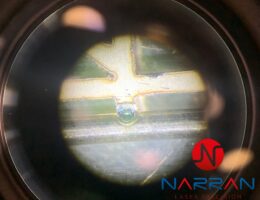

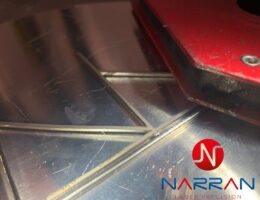

The project consisted of welding a 2 mm thick A2 stainless steel antenna, which was cut to shape using a Gwake fibre laser cutter. This antenna was then welded to a 1.5mm diameter A2 stainless steel log using a Sisma SWA 150 laser welder.

Technologies and materials used

- Laser welder: Sisma SWA 150

- Material: stainless steel A2 (parts 2 mm and rounds 1,5 mm)

- Cutting out the parts: Gweike lf3015gar

Welding machine parameters setting:

- Point size: 1.5 mm

- Pulse length: 0.8 ms

- Frequency: 10 Hz

- Power: 65% of 150 W (97.5 W)

- Protective gas: Argon (flow rate 10 l/min)

Sisma SWA 150 system description

Sisma SWA 150 is a modern laser welder designed for precision welding of metal materials. This system is characterized by high flexibility, easy operation and exceptional stability of the welding process. Key features include:

- Precise parameter settings: The ability to fine-tune pulse length, power and frequency ensures optimal results for different types of materials and applications.

- High performance: thanks to a maximum power of 150 W and a precise laser beam, quality welds can be achieved even with complex joints.

- Weld protection: an integrated shielding gas supply system (e.g. argon) minimizes oxidation and ensures aesthetic quality of the weld

- Ergonomic design: easy handling and intuitive controls allow quick set-up even for demanding tasks.

These features make the Sisma SWA 150 the ideal choice for applications that require high precision, such as welding thin-walled parts or small components with minimal thermal impact on the surrounding material.

Welding process:

-

- The laser beam was precisely focused on the junction between the antenna surface and the log.

- Welding was performed sequentially to minimize thermal distortion.

- The result was homogeneous welds of high strength and aesthetic quality.

Results

The use of the Sisma SWA 150 has brought several important advantages:

- Precision: the joints were absolutely precise, without deformations and visible defects.

- Speed: Laser welding enabled complex joints to be made quickly.

- High strength: The welds achieved mechanical properties that meet the requirements for industrial applications.

- Aesthetics: The joints were clean and required only minimal surface treatment.

Conclusion

The laser welding of the antenna with the Sisma SWA 150 was successful. This technology enables excellent joint quality to be achieved, even in complex and precise applications. In future projects of this type, laser welding is proving to be an indispensable technology for industrial practice. It is widely used in mould repair.

Related machines