Laserové řezání

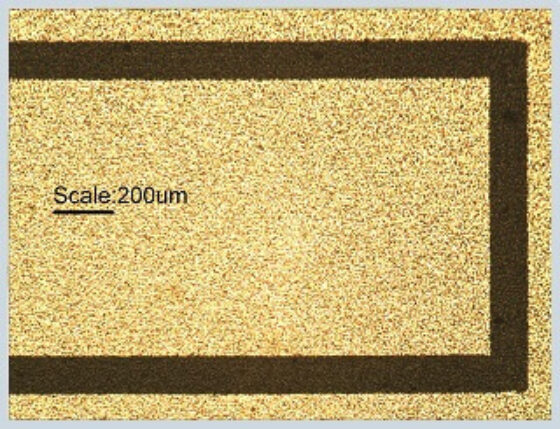

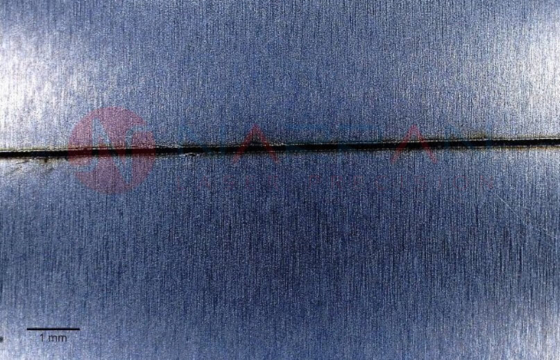

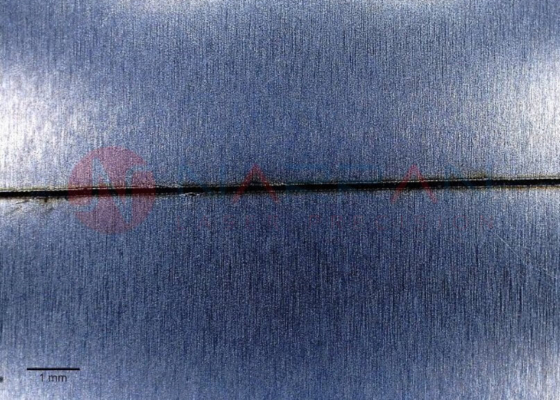

Laserové řezání má oproti tradičním řezacím metodám (vodní paprsek, vysekávače, plazma,..) mnoho výhod. Je rychlé, přesné a výsledný řez je dokonalejší než u ostatních používaných metod. Instalace laserového řezacího stroje dokáže výrazně zlevnit celý výrobní proces. Laserové stroje lze použít pro řezání kovových i nekovových materiálů.

CO2 laser

Používá se ve výkonech od 100 W pro řezání kyslíkem (tenké materiály v řádu milimetrů), od řádu kW pro řezání dusíkem, argonem, vzduchem. Oproti jiným typům laserům má nízkou účinnost (10%) a vysoké náklady na spotřební materiál a servis (pravidelná výměna fokusačních čoček, zrcadel, laser potřebuje pro svou činnost přívod 4 druhů plynů o vysoké čistotě + řezný plyn, budící VF stupeň je také spotřební materiál, je nutná pravidelná repase rezonátoru a naladění optické dráhy).

Vláknový laser

Používá se pro řezání od výkonu 500 W a je rentabilní do cca 3 kW. Laserový svazek je přiveden do stroje pomocí optického vlákna. Výkonnější řezací lasery bývají složeny z více modulů a při poruše jednoho modulu je možné pokračovat v práci se zbývajícími moduly (samozřejmě s nižším výkonem). Spotřebním materiálem u těchto řezacích laserů je pouze krycí sklo, případně keramický izolační kroužek a tryska. Nevýhodou může být vyšší pořizovací cena oproti CO2 laseru (vždy záleží na aplikaci).

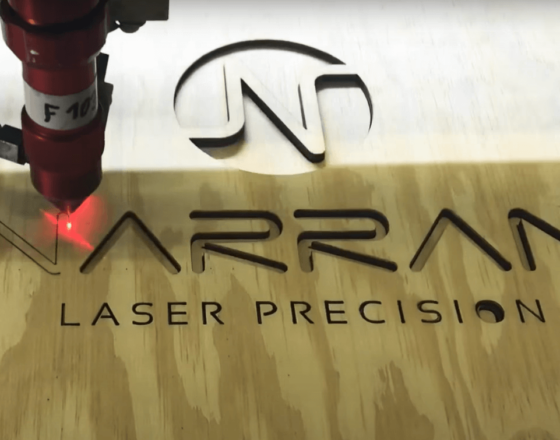

Proč si vybrat řešení od Narranu

Dokážeme poradit s výběrem již hotového řešení (stroje), i sestrojit stroj na míru (naše vlastní řešení, která vyrábíme pod názvem řady Narran Veles. S řezáním různých materiálů máme mnohaleté zkušenosti a dokážeme poradit dle přání zákazníka, s ohledem na rozpočet.

Zakázku zpracujeme od nápadu zákazníka, přes výběr/výrobu zařízení, až po zaškolení a následní servis stroje.

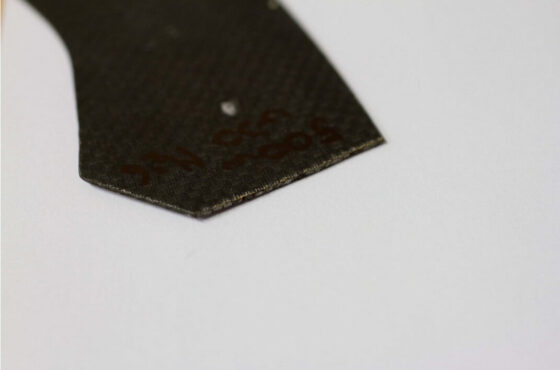

Nabízíme testování Vašich vzorků na našich strojích pro snadnější výběr vhodného řešení.

Běžné náhradní díly máme skladem a servis stroje řešíme pohotově dle potřeb zákazníka.

Výhody a funkce našich laserů

Vhodné materiály

Výhody řezání laserem oproti konvenčním metodám

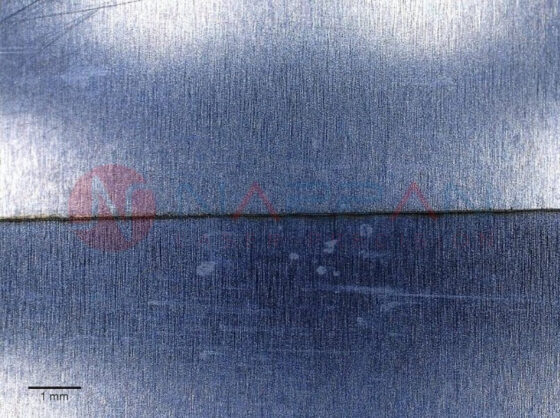

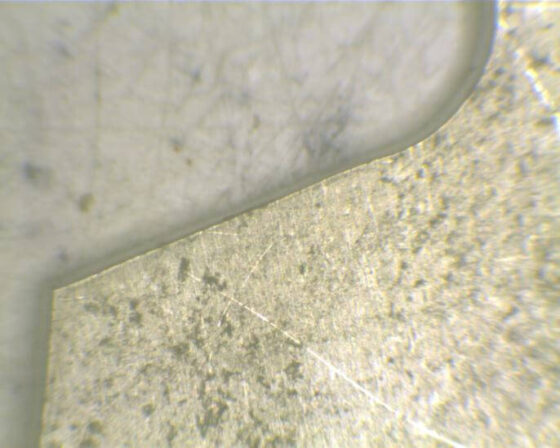

kvalita, rychlost a preciznost řezu

produktivita a efektivita práce je vysoká

při odpařování materiálu nevzniká téměř žádný odpad

řezací stroj lze integrovat do automatizovaného pracoviště

Na co je možné řezací laser využít?

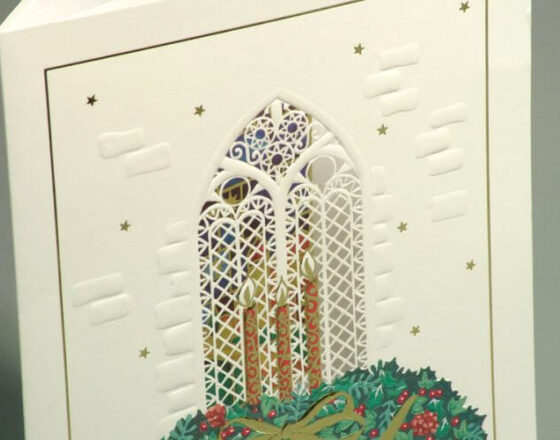

Takto používají laser naši klienti

Nabídka našich laserů