Industrial cleaning of labelling machines

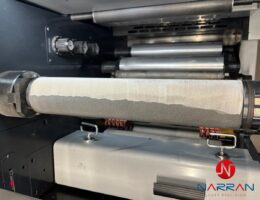

The customer required cleaning of the bearing rollers, which are clogged with glue and the production line is not able to meet the hygiene standards for the food industry.

Labelling machines in the food industry refer to equipment used in the packaging of food products with labels. The problem in cleaning these machines lies in the accumulation of dirt and contaminants such as adhesives, oils and food residues during operation. The complexity of the machines, adhesive build-up on components such as rollers and strict hygiene standards add to the difficulties. Cleaning requires thorough procedures to prevent cross-contamination and ensure compliance with food safety regulations. In addition, downtime during cleaning affects productivity, requiring efficient cleaning methods that minimize disruption to operations.

The laser’s main advantage in this case is that we can clean the feed rollers perfectly quickly and cleanly, which then meet the stringent requirements for labels that come into close contact with food. As the rollers do not need to be removed from the machine, a large amount of time is saved and the minimal amount of smoke generated during the removal of adhesives is extracted by the filter unit. Cleaning is therefore very quick and environmentally friendly compared to the chemical method that would otherwise be used.